The Role of Diamond Pads in Artisanal Stonework

Stoneworking is one of the oldest and most respected crafts in human history. From ancient monuments to modern sculptures, stone has been a symbol of both strength and artistry. However, the tools used in stoneworking have evolved dramatically over time, with one of the most important advancements being the introduction of diamond pads. These small yet powerful tools have become indispensable in the hands of artisans, revolutionizing the way they approach shaping, polishing, and finishing stone.

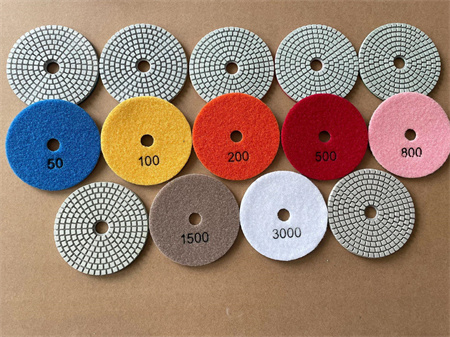

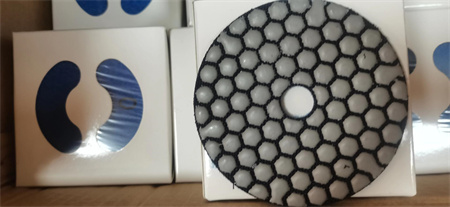

Diamond pads, as the name suggests, are embedded with tiny diamond particles, making them far more durable and effective than traditional abrasives. Unlike sandpaper or other stone grinding tools, diamond pads are designed to tackle the hardest materials with precision and speed, making them a game-changer for anyone involved in stoneworking, from skilled masons to contemporary sculptors.

One of the primary advantages of using diamond pads is their versatility. Stone comes in many forms, from the soft and porous varieties to dense, hard stones like granite and marble. For artisanal workers, selecting the right tools for the job is crucial, as each stone type requires different handling. Diamond pads offer a level of adaptability that allows craftsmen to work across various stone types with consistent results. Whether the task involves rough grinding to remove excess material or a fine polish to achieve a smooth, reflective finish, diamond pads deliver precision that other tools simply cannot match.

In addition to their versatility, diamond pads enhance the quality of the work. Stone surfaces can often be uneven, with natural blemishes or imperfections. Achieving a flawless finish has always been a challenge, particularly when working with materials that have been quarried from the earth. Diamond pads excel at smoothing out these inconsistencies, bringing out the natural beauty of the stone while ensuring a high-quality, professional result. Whether working on large sculptures or intricate stone tiles, these pads provide a uniform finish, free from the scratches or gouges that can often arise with inferior abrasive tools.

The speed at which diamond pads perform also sets them apart. In the past, artisans would spend hours or even days meticulously shaping and polishing stones by hand, using tools like chisels or files. While this process allowed for a great deal of artistry, it was time-consuming and labor-intensive. Diamond pads, however, make it possible to achieve similar or even superior results in a fraction of the time. This efficiency has made them particularly attractive to commercial stoneworkers and those involved in high-volume production, where time is often of the essence.

However, it’s not just the technical advantages that make diamond pads so essential in artisanal stonework—it’s also the way they enable creativity. When stone is too hard or uneven, the limitations of traditional tools can restrict an artisan’s ability to bring their vision to life. Diamond pads give stoneworkers the freedom to experiment and refine their designs with a precision and ease that would have been impossible in earlier times. Whether carving intricate details into a statue or polishing the edge of a countertop, the level of control afforded by these pads allows for greater artistic expression and a more refined outcome.

The longevity of diamond pads also makes them a cost-effective choice in the long run. While the initial investment in diamond pads may be higher than traditional abrasives, their durability means that they can outlast many other tools, providing value for money over time. Their long lifespan, combined with their high performance, ensures that artisans can achieve professional-grade results without constantly needing to replace worn-out tools.