Sourcing Diamond Pads for the North American Market

The diamond pad industry has seen remarkable growth, particularly in the North American market, as businesses across sectors increasingly demand high-quality products for polishing, grinding, and surface finishing. From manufacturing to construction and even in the automotive industry, the need for reliable, durable diamond pads is greater than ever. However, sourcing these products for North America involves more than just picking up the phone and placing an order. It requires understanding the market’s specific needs, navigating international supply chains, and selecting the right suppliers who can deliver consistency and performance.

North America’s industrial landscape is diverse, with companies ranging from small family-owned businesses to large corporations. As a result, sourcing diamond pads requires not only a clear understanding of the types of surfaces they’ll be used on but also an awareness of the preferences specific to the region. Companies are looking for products that can withstand long hours of heavy use, yet still provide a finish that meets the high standards expected in the market. Therefore, sourcing high-quality diamond pads means finding a manufacturer that offers the right balance between price, performance, and durability.

When searching for a reliable supplier, there are several factors to consider. One of the first steps is identifying whether a supplier can meet North America’s regulatory requirements. Depending on the state or province, there may be specific regulations regarding manufacturing standards, environmental considerations, and safety protocols. Suppliers based overseas must also be prepared to comply with these standards to ensure their products are market-ready.

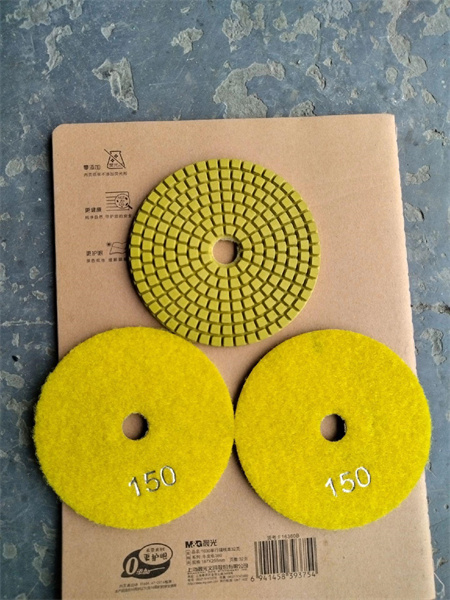

Another critical aspect of sourcing diamond pads is determining the level of customization required. In many cases, businesses need pads that are tailored to particular applications or materials. Some industries, like construction, may require pads that work on rougher, more abrasive surfaces, while others, such as automotive or aerospace, might demand pads that offer a finer, smoother finish. This variability means that a “one-size-fits-all” approach doesn’t often work for diamond pads. When selecting a supplier, it’s crucial to find one that has the capability to offer custom formulations or designs that will meet specific needs.

In recent years, technology has played a major role in advancing the quality and efficiency of diamond pads. Modern manufacturing processes allow for greater precision in the way the pads are made. For example, some manufacturers use advanced laser welding techniques to ensure the diamonds stay securely in place, providing longer life and better performance. Others have incorporated innovative bonding agents to improve the pad’s overall stability and heat resistance. With these technological advancements, companies sourcing diamond pads for the North American market have more options than ever to enhance the quality of their products.

In addition to shipping logistics, another key issue to consider is the impact of global supply chain disruptions. The COVID-19 pandemic, for example, exposed vulnerabilities in the global supply chain that are still being felt today. Even now, there are occasional delays in the production and delivery of raw materials, and finding reliable sources has become more challenging. Therefore, businesses looking to source diamond pads need to be proactive about managing potential supply chain disruptions and work with suppliers who have the flexibility to navigate these challenges.

Lastly, pricing is always a central factor when sourcing diamond pads. While businesses always want to find the best deal, it’s important to avoid the temptation of solely focusing on price, as this can lead to compromises in quality and performance. Cheaper pads may initially seem like a good choice, but they can wear out more quickly, resulting in more frequent replacements and, ultimately, higher costs in the long run. By carefully selecting suppliers who can offer high-quality products at competitive prices, businesses can ensure that they’re making an investment that will pay off over time.