Understanding the Role of Diamonds in Polishing Pads

When it comes to achieving a flawless, high-gloss finish, few materials can match the precision and efficiency of diamonds. While they are most commonly associated with jewelry, diamonds play a crucial role in industries like manufacturing, automotive, and even electronics, where polishing and surface finishing are essential. In particular, the use of diamonds in polishing pads has revolutionized the way we approach surface treatment, offering superior performance that other abrasives simply can’t replicate.

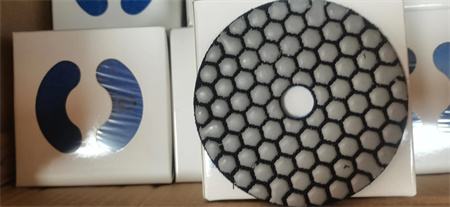

At its core, diamond is one of the hardest substances known to man, making it an ideal material for abrasive applications. Polishing pads, which are used to smooth out surfaces and bring out their shine, rely on abrasives to gradually remove small layers of material. For many applications, especially those involving tough materials like stone, metal, glass, and ceramics, using diamonds in polishing pads elevates the quality and speed of the polishing process.

Diamonds are also capable of achieving a level of finish that other abrasives simply can’t match. The exceptional hardness of diamond particles allows them to break down tough surface imperfections without damaging the underlying material. Whether you’re working on a delicate surface like polished marble or a hard material like steel, diamond polishing pads can deliver a consistent and flawless finish. The result is a smooth, glossy surface that not only looks great but also reduces friction, wear, and tear, adding to the durability of the finished product.

Moreover, diamond polishing pads are highly effective in reducing heat buildup during the polishing process. Traditional abrasives can generate excessive heat due to friction, which can cause warping or burning of the workpiece. However, diamonds’ exceptional thermal conductivity helps dissipate heat more efficiently, ensuring a smoother, more controlled polishing process. This characteristic is particularly useful when working with heat-sensitive materials or when maintaining the integrity of the surface is of utmost importance.

The benefits of using diamonds in polishing pads aren’t limited to their performance on hard surfaces. These pads are also highly effective in finishing softer materials with a delicate touch. Whether it’s polishing automotive parts, removing scratches from glass surfaces, or achieving a high-gloss finish on stone floors, diamond-infused polishing pads provide unparalleled precision. Their ability to smooth out even the tiniest imperfections ensures that the final product has an impeccable appearance, free from flaws or inconsistencies.

As industries continue to push the limits of precision and quality, diamond polishing pads are becoming an essential tool for achieving the highest standards of surface treatment. From luxury finishes in the automotive and architectural sectors to precision engineering and delicate electronics manufacturing, the use of diamonds in polishing pads offers unmatched benefits in terms of speed, durability, and finish quality.

In conclusion, the role of diamonds in polishing pads is not just about their striking appearance or high value—they are a game-changer in the world of surface finishing. Their unparalleled hardness, longevity, and ability to achieve a flawless finish make them indispensable in a wide range of industries. Whether you’re polishing a piece of fine jewelry, smoothing a stone countertop, or working on high-precision machinery, diamond-infused polishing pads provide the superior results that are essential for maintaining quality and performance. As technology and manufacturing processes continue to evolve, it’s clear that diamonds will remain at the forefront of innovation in polishing and surface finishing.