Why Diamond Pads Are Ideal for Industrial Floor Polishing

When it comes to industrial floor polishing, achieving a smooth, durable, and high-quality finish is essential. One of the most effective tools for the job is diamond pads. These powerful pads, equipped with industrial-grade diamond abrasives, are becoming the go-to choice for businesses seeking both efficiency and long-lasting results in their floor maintenance.

Unmatched Durability and Strength

Diamonds are known for their hardness and resistance to wear, making diamond pads incredibly durable. Unlike other abrasive materials, diamond is the hardest natural substance on earth. This gives diamond pads an edge over traditional alternatives, allowing them to withstand the tough conditions of industrial environments without losing their efficiency. While other pads may degrade quickly, diamond pads retain their cutting power, delivering consistent results over time.

Superior Polishing Results

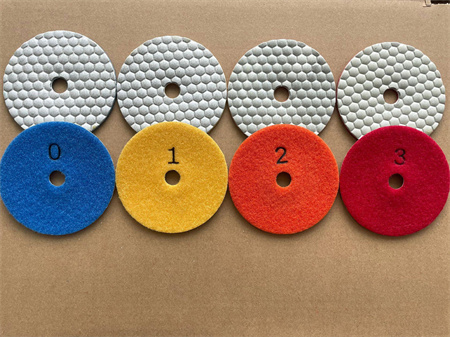

For industrial floor polishing, the quality of the finish matters. Diamond pads are able to provide a superior level of polish, transforming dull, worn-out floors into high-gloss, visually appealing surfaces. The precision of diamond abrasives ensures an even, smooth finish with minimal effort. The finer the grit of the diamond pad, the higher the level of polish that can be achieved, allowing for a glass-like shine that reflects light beautifully and elevates the overall aesthetic of the space.

Additionally, diamond pads can be used for both wet and dry polishing. This flexibility makes them versatile for different environments and types of floors. Wet polishing helps reduce dust and keeps the floor cool during the process, while dry polishing speeds up the job and allows for immediate use of the space afterward. The result is always a clean, shiny surface that impresses visitors and employees alike.

Increased Efficiency and Faster Results

In the world of industrial floor care, time is money. With their unmatched cutting ability, diamond pads can quickly achieve the desired results without requiring excessive labor or time. Their aggressive abrasion allows them to cut through rough surfaces, remove imperfections, and refine the floor much faster than traditional abrasives. This makes them particularly advantageous in large spaces or high-traffic areas where downtime must be kept to a minimum.

Because they require less downtime and fewer passes to achieve a polished floor, diamond pads also help reduce labor costs. Whether it’s an annual floor restoration or a routine maintenance job, using diamond pads can significantly improve efficiency, allowing workers to complete tasks more quickly while still achieving high-quality results.

Cost-Effectiveness in the Long Run

While diamond pads may have a higher initial cost compared to other floor polishing products, their durability and longevity make them a more cost-effective solution over time. Because they last longer and require fewer replacements, the total cost of ownership is considerably lower. Additionally, their efficiency in the polishing process means less time spent per project, which can lead to savings in labor costs.

Another factor that contributes to their cost-effectiveness is their ability to be used across various floor types and for multiple stages of the polishing process. With the right grit sequence, diamond pads can grind, hone, and polish the floor all with the same set, saving both time and money in the process.

Eco-Friendly and Sustainable

Sustainability is becoming increasingly important in the industrial world, and diamond pads play a role in reducing environmental impact. Unlike pads made with harsh chemicals or materials, diamond pads don’t require any special chemicals for polishing. The natural abrasiveness of the diamond particles is sufficient to achieve a clean, smooth floor without the need for harmful substances. Furthermore, the long lifespan of diamond pads reduces the need for frequent replacements, lowering the environmental impact over time.

Another reason diamond pads are ideal for industrial floor polishing is their versatility. They can be used on a variety of floor types, including concrete, marble, granite, terrazzo, and more. Whether you’re dealing with a factory floor, a showroom, or a warehouse, diamond pads can adapt to the specific requirements of each surface.

This versatility makes diamond pads a practical investment for businesses that manage different types of flooring within their facilities. No matter the material, these pads can deliver consistent, high-quality results, making them a one-stop solution for all your floor polishing needs.

In Conclusion

The rise in popularity of diamond pads in industrial floor polishing isn’t just a trend—it’s a reflection of their undeniable advantages. With unmatched durability, superior polishing results, increased efficiency, and long-term cost savings, diamond pads have become the industry standard. If you’re looking to maintain floors that look pristine, withstand heavy use, and require minimal maintenance, diamond pads are the tool to invest in. Whether it’s for a small facility or a sprawling industrial complex, diamond pads provide a reliable, sustainable, and effective solution that ensures your floors remain in top condition for years to come.