When it comes to choosing the perfect diamond polishing pads for your project, there are a few key factors that can make all the difference between achieving a flawless finish and ending up with subpar results. Whether you’re polishing marble, granite, concrete, or another stone surface, selecting the right pad is essential for both quality and efficiency. Here’s what to look for when buying diamond polishing pads.

Quality of Diamond Grit

One of the first things to consider when choosing diamond polishing pads is the quality of the diamond grit. Diamonds are the hardest natural material on earth, and the quality of the diamond used in the pad will directly impact its effectiveness. High-quality diamonds will provide a smoother, more consistent finish and last longer, making them an excellent investment. Look for pads that use industrial-grade diamonds, as these will give you the best results, especially for heavy-duty polishing tasks.

Pad Flexibility and Thickness

Not all surfaces are the same, and neither are the pads that you use to polish them. The flexibility and thickness of the pad can determine how well it conforms to the surface you’re working on. If you’re polishing intricate or uneven surfaces, such as a countertop with curved edges, you’ll want a pad that offers good flexibility. On the other hand, for flat surfaces like floors, you may prefer a thicker pad for more consistent pressure distribution and durability.

Bonding Matrix

The bonding matrix holds the diamond grit together, and its composition can influence how the pad performs. A soft bond works best for polishing harder materials, while a harder bond is more suitable for softer materials. The bond also plays a role in how quickly the diamonds wear down, which affects how long the pad will last. Consider your specific project needs and select a pad with the appropriate bonding strength to maximize both performance and lifespan.

Polishing pads come in a range of grits, from coarse to fine, and understanding which one you need is crucial for achieving the desired outcome. Coarse pads (30-50 grit) are designed for heavy grinding and shaping, while medium pads (100-200 grit) are perfect for removing scratches and imperfections. Fine pads (400-3000 grit) are used for polishing and achieving a high-gloss finish. Depending on the level of refinement you need, you may need to purchase several different pads to move through the necessary stages of the polishing process.

Durability and Longevity

Durability is one of the most important aspects when selecting diamond polishing pads. Low-quality pads can wear down quickly, leading to frequent replacements and potentially causing inconsistent results. High-quality diamond pads are designed to withstand heavy use, and they’ll keep their performance throughout the job. To ensure you get the best value for your money, choose pads from reputable brands known for their long-lasting durability. It’s also worth checking reviews or talking to others who’ve used the pads to get an idea of how well they hold up over time.

Wet vs. Dry Pads

Polishing can be done either wet or dry, and some pads are designed for one or the other, while others can work in both environments. Wet polishing is often preferred for reducing heat and preventing dust, especially when working with harder stones like granite. Dry pads are more convenient for quick jobs but might produce more heat and dust. Depending on the type of stone you’re polishing and your specific needs, you may need to choose between wet or dry pads—or, if versatility is key, a pad that can handle both.

Pad Size

The size of the pad is also an important consideration, as it should be compatible with your polishing machine. Most diamond polishing pads come in standard sizes such as 4-inch, 5-inch, or 6-inch, but it’s important to make sure the pad matches the specifications of your tool. A well-fitted pad will ensure that you maintain consistent pressure and coverage, which is essential for achieving an even, smooth finish. If you’re working on large areas or floors, larger pads might be more efficient. Smaller pads can provide more control for detailed work.

Ease of Use

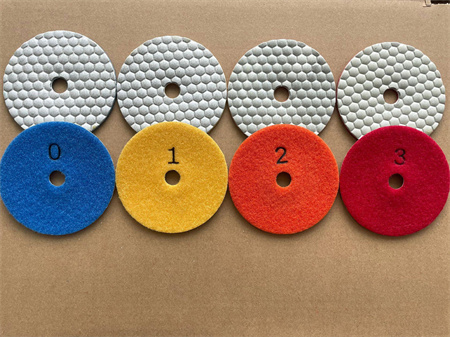

Finally, think about the ease of use and convenience when selecting your pads. A good diamond polishing pad should be easy to attach and remove from your polishing machine, with features like Velcro backing making it simple to swap out pads as needed. Some pads also come with color-coding, making it easier to identify different grit levels and avoid mixing them up during the polishing process.

Price and Value for Money

Choosing the right diamond polishing pad is crucial for ensuring that your stone surfaces are polished to perfection. By focusing on factors like diamond quality, pad flexibility, grit rating, and durability, you can make an informed decision that will help you achieve the results you want. Whether you’re working on a small countertop or a large commercial floor, the right polishing pad can make your job smoother, faster, and more professional-looking. Take the time to choose wisely, and your polished surfaces will shine like never before.