Why Contractors Prefer Durable Diamond Polishing Pads

In the world of construction and renovation, contractors constantly seek tools and materials that enhance their work efficiency and deliver high-quality results. One such tool that has become a contractor’s essential is the diamond polishing pad. These pads are used extensively for polishing concrete, marble, granite, and other stone surfaces, and their durability is a major reason why they’re so highly preferred. Let’s take a deeper look at why contractors swear by the long-lasting power of diamond polishing pads.

First and foremost, durability in the construction industry is non-negotiable. Projects often require finishing tasks that involve working on tough surfaces, and any tool used in the process needs to withstand constant wear and tear. Unlike traditional polishing pads, which may wear out quickly, diamond polishing pads are built to endure heavy-duty tasks. The abrasive diamond particles embedded in the pad’s surface provide a strong, long-lasting material that can handle prolonged use without losing efficiency. This means that contractors can complete multiple jobs using the same pad, reducing the need for frequent replacements, saving both time and money.

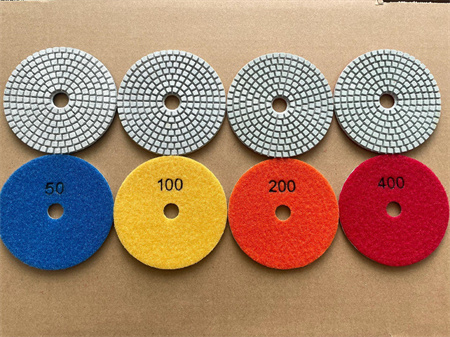

Contractors also appreciate the versatility of diamond polishing pads. Whether it’s a small residential project or a large-scale commercial job, diamond pads can be used on a variety of surfaces, including concrete, granite, marble, and even terrazzo. This adaptability allows contractors to rely on one tool for multiple applications, further enhancing their operational efficiency. The wide range of grit levels also makes them suitable for different stages of the polishing process, from coarse grinding to fine polishing. This versatility ensures that contractors can achieve the exact finish they desire on each job, whether they’re aiming for a matte, satin, or glossy shine.

Another key benefit of diamond polishing pads is the superior finish they leave behind. Unlike other types of polishing pads, diamond pads are capable of producing a much smoother and more consistent surface. The diamonds themselves, being one of the hardest materials known to man, cut through tougher surfaces with ease, allowing contractors to achieve a high-quality result without much effort. Whether working on marble countertops or polished concrete floors, the finish is sleek and uniform, adding a professional touch that meets the high standards of clients and customers alike.

The time-saving aspect is also something that contractors can’t overlook. Diamond polishing pads, due to their superior durability and effectiveness, often reduce the amount of time spent on each polishing job. This is especially crucial for contractors working under tight deadlines or managing multiple projects simultaneously. The faster and more efficiently they can complete a polishing task, the more time they have to move on to other essential parts of the project. This can significantly boost productivity, ensuring that contractors meet client expectations without compromising on quality.

Safety is another reason why contractors are drawn to diamond polishing pads. With construction work involving heavy machinery and high-risk environments, having reliable, high-quality tools is vital. Diamond polishing pads are engineered to offer superior control and stability during use. The high-quality design reduces the risk of wear and tear that could lead to accidents or inferior performance. Since the pads are designed to handle tough materials, contractors are less likely to encounter issues such as clogging or pad degradation that can occur with inferior products, which could affect both safety and the quality of the finished work.

Finally, contractors value the consistent performance of diamond polishing pads. The quality control standards for these pads are high, ensuring that each product performs as expected. Contractors can trust that when they use a diamond polishing pad, it will deliver the same exceptional results every time. This reliability is a key factor in building long-term relationships with clients, as it ensures that their projects will always meet or exceed expectations.

In conclusion, the preference for durable diamond polishing pads among contractors comes down to their remarkable longevity, versatility, and superior finish. These pads not only save time and money but also provide the consistency and high-quality results that contractors need to maintain their reputation and meet client demands. With their durability and cost-effectiveness, diamond polishing pads continue to be a go-to choice for contractors looking to deliver top-notch results on every project.