Why Grit Transition Matters in Multi-Step Polishing

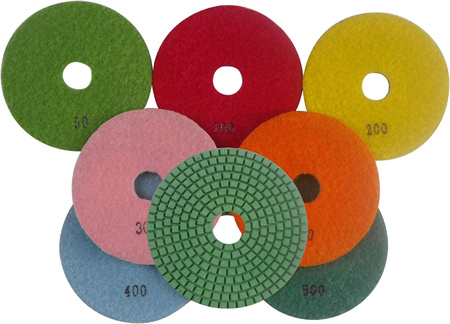

The foundation of a high-quality polish begins with the choice of grits. Each grit size serves a different purpose in the polishing cycle, and each step should build on the previous one. Starting with too fine a grit or skipping an essential step can lead to a number of issues: scratches that won’t come out, uneven finishes, or longer polishing times. On the flip side, jumping straight into finer grits without adequate use of coarser ones can leave behind rough patches and imperfections.

Coarse abrasives (typically the first stage) are used to remove the bulk of imperfections from the surface. Whether it’s heavy scratches, discoloration, or surface contamination, the goal is to make the surface as smooth as possible at a macro level. But these coarser abrasives leave visible scratches or marks on the surface, which are expected. These marks are much deeper than those made by finer grits, and if you were to attempt finishing with such scratches still present, they would be magnified and apparent in the final polish.

Now comes the real beauty of grit transition – the gradual progression from coarse to fine grits. The magic lies in how each finer grit erases the previous one’s imperfections. After the initial, coarse stage, a medium-grit abrasive will start smoothing out the rough scratches left behind. This step is important for eliminating the deeper scratches while setting the stage for a finer finish. The grit size used here may vary depending on the material and the level of precision required.

The significance of grit transition extends beyond aesthetics; it directly impacts the efficiency of the polishing process. Using the correct grit progression allows you to work with less effort at each stage. For example, if you’ve used a coarse abrasive effectively, you’ll have less to do with the medium and fine abrasives. You won’t be trying to remove deep scratches that should have been dealt with earlier in the process. Instead, you’ll focus on refining the surface and getting the smooth, glossy finish you’re after with minimal effort.

Additionally, grit transition plays a crucial role in the longevity of your polished surface. A poorly executed transition, or a rushed polishing process, can lead to a finish that wears off more quickly or shows signs of degradation sooner than it should. When done properly, however, each step of the polishing cycle helps to preserve and enhance the durability of the surface. This is particularly vital for industries where precision and lasting quality are paramount, such as automotive, aerospace, and fine art restoration.

Finally, understanding grit transition is also about knowing the limits of your material and your tools. Some materials require more careful attention, while others are more forgiving. As you move from one grit size to the next, you should also be adjusting your pressure, speed, and technique to match the material’s needs. Over-polishing or using too fine a grit on a soft material can create surface damage or even cause the material to become overly polished, resulting in a dull appearance.

In conclusion, grit transition in multi-step polishing is not just an optional consideration – it’s an essential part of the process that determines the outcome. It ensures that each stage builds on the last to create a smooth, even, and flawless finish. It saves time, improves results, and preserves the integrity of the material. Whether you’re polishing a piece of jewelry, an industrial component, or an art piece, paying careful attention to grit transition will make all the difference between a good finish and a great one.