Title: Polishing Bluestone with Diamond Pads: An Expert’s Guide

When it comes to achieving a flawless, high-gloss finish on bluestone, the key to success lies in using the right tools. Diamond polishing pads are renowned for their exceptional performance and durability, making them the go-to choice for professionals in the stone finishing industry. As a leading manufacturer of diamond polishing pads, we’re here to guide you through the process of polishing bluestone, offering tips and insights that will help you achieve a superior finish.

Understanding Bluestone and Its Challenges

Bluestone, known for its durability and natural beauty, is a popular choice for both residential and commercial applications. However, its dense, tough surface can pose challenges during the polishing process. Bluestone often requires specialized equipment and techniques to achieve the desired smoothness and sheen. This is where diamond polishing pads come into play.

Why Diamond Polishing Pads?

Diamond polishing pads are favored for their effectiveness in handling tough materials like bluestone. The secret behind their superior performance lies in the diamond particles embedded in the pad. These particles are incredibly hard and provide exceptional cutting power, enabling them to grind and polish even the hardest surfaces with ease.

1. Durability: Diamond pads are known for their long lifespan. Unlike traditional abrasives that wear down quickly, diamond pads maintain their effectiveness over numerous polishing sessions, offering long-term value.

2. Efficiency: The high cutting power of diamond pads ensures that you can achieve a smooth and glossy finish faster than with other polishing materials.

3. Versatility: While diamond pads are ideal for bluestone, they are also effective on a variety of other stones and surfaces, making them a versatile tool in any stone care toolkit.

Choosing the Right Diamond Polishing Pads

Selecting the appropriate diamond polishing pads is crucial for achieving optimal results. Here are some factors to consider:

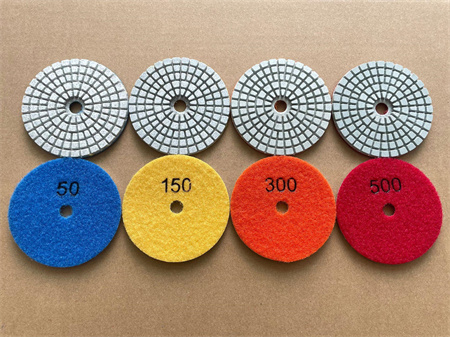

1. Grit Size: Diamond polishing pads come in various grit sizes, ranging from coarse to fine. For bluestone, starting with a coarse grit pad to remove imperfections and then progressively moving to finer grits will ensure a smooth and polished finish.

2. Pad Type: There are different types of diamond pads, including wet and dry options. Wet diamond pads are used with water to cool the surface and reduce dust, while dry pads are used for quick, dust-free polishing. For bluestone, wet polishing is often preferred to prevent overheating and to manage dust.

3. Backing Material: The backing material of the pad can affect its flexibility and performance. Look for pads with a durable, flexible backing that can conform to the surface of the bluestone, especially when dealing with irregular or textured areas.

The Polishing Process

1. Preparation: Before you start polishing, ensure that the bluestone surface is clean and free of debris. Any dirt or grit on the surface can cause scratches during polishing.

3. Progressive Polishing: Gradually move to finer grit pads, working your way up through the grits. Each successive pad should refine the surface, removing the scratches left by the previous pad and enhancing the shine.

4. Finishing Touch: For the final step, use a high-grit diamond pad to achieve a high-gloss finish. This step will bring out the natural luster of the bluestone and give it a polished look.

Maintaining Your Diamond Polishing Pads

To ensure the longevity and performance of your diamond polishing pads, proper maintenance is crucial:

1. Cleaning: After each use, clean the pads thoroughly to remove any residue or debris. This helps prevent clogging and maintains the effectiveness of the diamond particles.

2. Storage: Store the pads in a dry, cool place to prevent damage. Avoid exposing them to extreme temperatures or moisture.

Applications and Benefits

The use of diamond polishing pads extends beyond bluestone. They are widely used in various industries for polishing and finishing other types of natural stone, concrete, and engineered surfaces. Whether you’re a wholesaler, importer, or retailer, offering diamond polishing pads can significantly enhance your product lineup and cater to a broader range of customer needs.

Conclusion

Polishing bluestone with diamond pads is a highly effective method for achieving a beautiful, high-gloss finish. By understanding the properties of bluestone and selecting the appropriate diamond polishing pads, you can ensure a professional and lasting result. As a manufacturer dedicated to providing top-quality diamond polishing pads, we are here to support your needs and help you achieve the best possible outcomes for your stone polishing projects.