The Impact of Grit Variation in Professional Stone Polishing

When it comes to professional stone polishing, grit variation is like the secret ingredient in a master chef’s recipe. It’s the subtle difference that can elevate a polished surface from good to spectacular. Whether you’re an importer, wholesaler, or retailer in the stone polishing industry, understanding how different grits affect the final product is essential for making informed decisions about your diamond polishing pads.

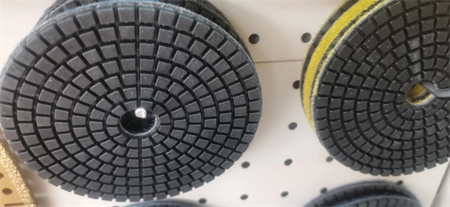

Firstly, let’s delve into what grit variation actually means. Grit size refers to the coarseness or fineness of the abrasive particles embedded in a polishing pad. Coarser grits, such as 50 or 100, are used for the initial stages of stone polishing, where the goal is to remove imperfections and rough spots. Finer grits, ranging from 2000 to 3000, are utilized in the final stages to achieve a high-gloss finish.

The ultimate impact of grit variation is evident in the quality of the final finish. Coarser grits are effective at cutting through the rough surface and shaping the stone, but they also leave scratches that must be addressed with progressively finer grits. Using the right sequence of grits ensures that these scratches are removed and the stone’s natural luster is brought out. For instance, starting with a 100 grit pad and progressing to a 3000 grit pad will result in a smoother, more polished surface compared to using only a single grit type.

For wholesale distributors and retailers, offering a range of grit sizes can cater to the diverse needs of your clients. Importers looking to stock up on diamond polishing pads should consider how different grits are essential for various stages of the polishing process. It’s not just about the product; it’s about providing a comprehensive solution for stone care.

In addition, understanding the grit variation helps in cost management. Higher grit pads are generally more expensive due to the finer abrasive particles used, so knowing when and where to use them can optimize both performance and budget. For example, investing in a high-quality 3000 grit pad for the final finish can make a significant difference in achieving the ultimate shine, while using coarser grits for initial work is more cost-effective.

For those in the business of manufacturing or importing diamond polishing pads, it’s crucial to communicate the significance of grit variation to your customers. Highlighting how different grits affect the polishing process and end results can set your products apart from competitors. Providing detailed information about grit sizes and their specific uses can also help clients make informed purchasing decisions.