Title: How to Find Customizable Diamond Pads for Unique Projects

Finding the perfect diamond pads for your specific needs can be a bit like searching for a needle in a haystack, especially when your project requires something truly unique. Whether you’re a wholesaler, importer, or retailer, understanding how to navigate the world of customizable diamond polishing pads can make all the difference. Here’s a comprehensive guide on how to find diamond pads that can be tailored to meet your exact specifications.

Understanding Diamond Pads

Diamond polishing pads are essential tools used in a variety of industries, from construction and flooring to automotive and stonework. They are renowned for their durability and effectiveness in polishing and grinding hard surfaces. The customization of these pads allows for precision in different applications, whether it’s for achieving a high gloss finish on granite or for fine-tuning a smooth surface on concrete.

1. Identifying Your Specific Needs

The first step in finding the right customizable diamond pads is to clearly define your project requirements. Consider the following factors:

– Type of Surface: Different surfaces require different types of diamond pads. For example, concrete surfaces might need pads with a coarser grit, while marble or granite may require finer, more delicate options.

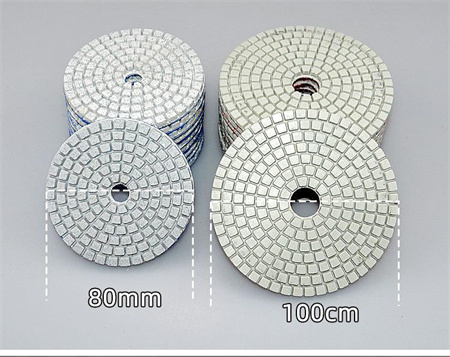

– Pad Size and Shape: Customizable diamond pads can come in various sizes and shapes, including circular, rectangular, or even custom shapes to fit specific machinery.

– Grit Levels: The grit level of the diamond pad affects its polishing ability. For a finer polish, a higher grit level is needed. Determine if you need a pad for heavy grinding or fine finishing.

– Backing Material: The backing material of the diamond pad can impact its flexibility and how well it adheres to different surfaces.

2. Researching Manufacturers and Suppliers

Once you have a clear understanding of your needs, the next step is to find reputable manufacturers and suppliers who offer customizable options. Look for companies that have a strong reputation for quality and reliability. Here are some tips for researching suppliers:

– Reviews and Testimonials: Check customer reviews and testimonials to gauge the reliability and quality of the products. This can provide insights into the company’s customer service and product performance.

– Certifications and Standards: Ensure that the manufacturer adheres to industry standards and holds relevant certifications. This can be an indicator of their commitment to quality and safety.

3. Exploring Customization Options

– Custom Shapes and Sizes: Can they create pads in specific shapes or sizes to fit your unique equipment or project requirements?

– Specialized Grit Combinations: Can they provide pads with custom grit combinations tailored to your specific polishing or grinding needs?

– Material Choices: Are there options for different backing materials or pad compositions to meet your specific needs?

– Prototype Development: Does the manufacturer offer prototype services to test and refine the pad before full-scale production?

4. Comparing Costs and Lead Times

Cost and lead time are critical factors when choosing a supplier. Obtain quotes from multiple manufacturers and compare them based on the following:

– Unit Price: Consider the cost per unit and how it aligns with your budget.

– Minimum Order Quantities: Check if there are minimum order requirements and how they affect your overall cost.

– Production Time: Understand the lead times for production and delivery to ensure they meet your project deadlines.

– Shipping Costs: Factor in shipping costs, especially if you’re importing pads from overseas.

5. Ensuring Quality Control

Before finalizing your order, ensure that the manufacturer has robust quality control processes in place. Request information on their quality assurance procedures and, if possible, visit their facility or request samples to verify the product quality.

6. Building a Long-Term Relationship

Building a strong relationship with a reliable supplier can be beneficial for future projects. Look for manufacturers who offer excellent customer support and are willing to collaborate on future customizations.

Conclusion

Finding the right customizable diamond pads for your unique projects requires a clear understanding of your needs, thorough research, and careful consideration of various factors such as customization options, costs, and quality control. By following these steps, you can ensure that you find the perfect pads tailored to your specific requirements, ultimately leading to successful and high-quality project outcomes.

Whether you’re a wholesaler, importer, or retailer, taking the time to find a dependable manufacturer and customizing your diamond pads will contribute significantly to the success of your projects and satisfy your customers’ needs.