Emerging Trends in Abrasive Tools Manufacturing

One significant trend is the increasing adoption of advanced materials and technologies. Traditional abrasives are being supplemented or replaced by high-performance materials like synthetic diamonds and advanced ceramics. These innovations enhance the durability, efficiency, and precision of abrasive tools, meeting the growing demands of various industries.

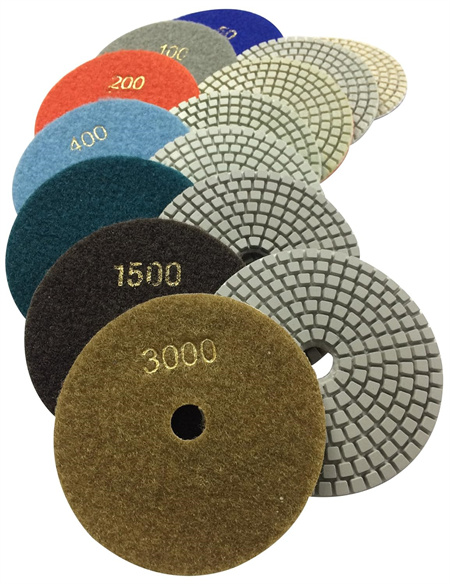

Customization is also on the rise. With industries requiring specific solutions for unique applications, manufacturers are focusing on developing customizable abrasive tools. For example, diamond polishing pads are increasingly tailored to suit various surface types and finishing requirements. This level of personalization ensures that customers receive products that best meet their needs.

Technological advancements play a pivotal role in this evolution. Automation and precision engineering are enhancing the production process, resulting in higher quality and consistency. The integration of smart technologies, such as sensors and real-time data monitoring, allows for more efficient manufacturing and improved product performance.

Moreover, the global market for abrasive tools is expanding, driven by rising demand in sectors such as construction, automotive, and aerospace. This growth is accompanied by a surge in international trade, with companies seeking reliable suppliers and manufacturers. As a result, the competitive landscape is becoming more dynamic, emphasizing the importance of innovation and quality.

For wholesale buyers and importers, understanding these trends is crucial in selecting the right suppliers. It’s essential to choose manufacturers who not only offer high-quality products but also demonstrate a commitment to technological advancements and sustainability. This ensures that businesses can provide their customers with the latest and most effective abrasive tools.

In summary, the abrasive tools manufacturing industry is experiencing transformative changes. From advanced materials and eco-friendly practices to customization and technological integration, these trends are shaping the future of abrasive tools. For importers, wholesalers, and retailers, staying informed about these developments is key to staying competitive in a rapidly evolving market.