To achieve a glossy finish on sandstone using diamond tools, you must follow a detailed process that ensures both efficiency and quality. Let’s dive into the ultimate guide for polishing sandstone to a brilliant shine, making use of diamond polishing pads and other diamond tools.

Understanding Sandstone and Diamond Tools

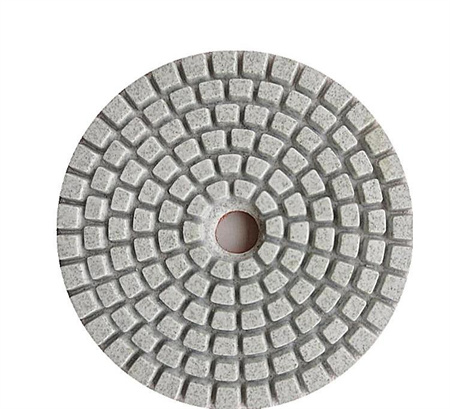

Sandstone, with its naturally porous and gritty texture, poses a challenge for achieving a high-gloss finish. Diamond tools, including diamond polishing pads, are the ultimate solution. These pads are specifically designed to handle the hardness of stone and provide a smooth, polished surface. When choosing diamond tools, it is crucial to select those with the right grit and quality to match your project needs.

Preparation

Before diving into polishing, proper preparation is essential. Start by thoroughly cleaning the sandstone surface to remove any dirt, debris, or old coatings. Any imperfections or deep scratches should be addressed using a diamond grinding tool. This step ensures that the surface is even and ready for the polishing process.

Selecting the Right Diamond Polishing Pads

Diamond polishing pads come in various grits, typically ranging from 50 to 3000. For sandstone, you will start with a coarser grit to remove the initial layers of material and then progress to finer grits for a smoother finish. The sequence usually begins with 50 or 100 grit, moving through 200, 400, 800, and so forth, until you reach the desired gloss.

Polishing Process

1. Start with Coarse Grit: Attach the coarse grit diamond polishing pad to your polishing machine. Begin working the pad over the sandstone in small sections, applying consistent pressure. This will remove the initial roughness and any larger imperfections.

2. Progress to Medium Grits: Once the surface is relatively smooth, switch to a medium grit pad (around 400 to 800). This stage is about refining the surface and preparing it for finer polishing.

3. Fine Polishing: As you move to finer grits (1500 and 3000), the goal is to achieve a high-gloss finish. Use each pad in succession, ensuring that you thoroughly clean the surface between each grit to avoid cross-contamination.

4. Final Touch: For the ultimate glossy finish, use a diamond polishing pad with a very fine grit, often accompanied by a polishing compound. This final step ensures that the sandstone surface is not only smooth but also shines brilliantly.

Maintenance and Care

After achieving the glossy finish, maintaining it is key. Regular cleaning with a gentle, non-abrasive cleaner will help preserve the shine. Additionally, using a sealant can protect the sandstone from stains and further damage.

Benefits of Diamond Polishing Pads

Industry and Market Insights

In the B2B market, diamond polishing pads are widely used by importers, wholesalers, and store owners. They are essential for businesses involved in the stone processing industry, including those specializing in marble, granite, and other natural stones. If you’re looking to source high-quality diamond polishing pads, it’s important to consider factors such as grit size, pad durability, and the specific requirements of your sandstone projects.

In conclusion, achieving a glossy finish on sandstone with diamond tools requires careful selection of pads, a systematic polishing process, and ongoing maintenance. By following these steps, you can ensure a stunning, high-quality result that highlights the natural beauty of sandstone.