Diamond Pads Buying Guide for First-Time Buyers

Welcome to the world of diamond polishing pads! If you’re a first-time buyer, you might feel overwhelmed by the array of options available. Fear not, as we will guide you through the essentials to make an informed decision that best suits your needs.

Understanding Diamond Polishing Pads

Diamond polishing pads are indispensable tools used for grinding and polishing surfaces, especially in the stone and concrete industries. These pads are embedded with industrial-grade diamonds, which make them highly effective for achieving a high-quality finish. Their applications range from polishing granite, marble, and concrete to other hard surfaces.

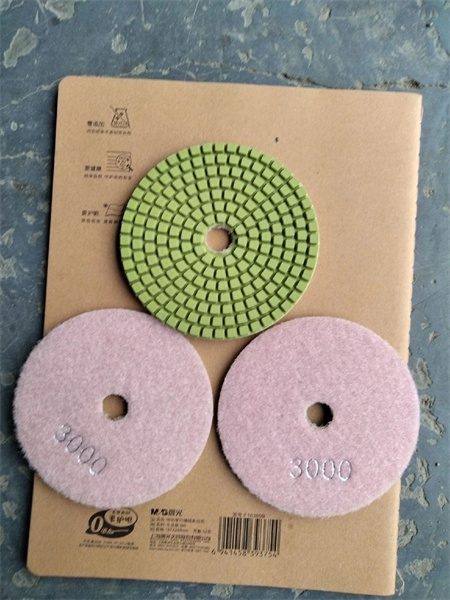

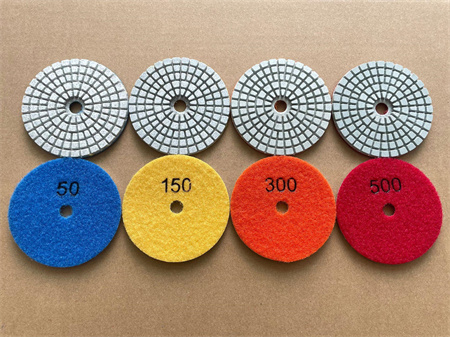

1. Wet vs. Dry Pads: Wet pads are used with water and are ideal for polishing stone surfaces, as the water helps to cool the pad and reduce dust. Dry pads, on the other hand, are used without water and are suitable for surfaces where water is not desirable or practical.

2. Flexibility: Polishing pads come in various flexibility levels. Flexible pads are great for uneven surfaces and intricate work, while rigid pads are ideal for flat, even surfaces.

3. Grit Sizes: Grit size determines the coarseness or fineness of the pad. Coarse pads (lower grit numbers) are used for heavy grinding, while finer pads (higher grit numbers) are used for polishing to a high shine.

Choosing the Right Pad

When selecting a diamond polishing pad, consider the following:

1. Surface Type: Identify the type of surface you will be working on. For granite or marble, use diamond pads specifically designed for stone. For concrete, choose pads that are optimized for hard, abrasive surfaces.

2. Pad Size: Ensure the pad size matches the equipment you are using. Common sizes include 4 inches and 7 inches, but always check compatibility with your machine.

Key Considerations for First-Time Buyers

1. Durability: Look for pads that offer durability and long-lasting performance. High-quality diamond pads may have a higher initial cost but can be more economical in the long run due to their longevity.

3. Price vs. Quality: Balance your budget with the quality of the pads. While cheaper pads may seem appealing, they might not offer the performance and lifespan you need.

4. Reviews and Ratings: Research customer reviews and ratings to gauge the effectiveness and reliability of the pads you are considering. This feedback can provide valuable insights into the performance and durability of the pads.

Buying in Bulk

If you’re a wholesaler, importer, or store owner, buying in bulk can offer cost savings and ensure you have a steady supply of pads. When buying wholesale, ensure you establish a good relationship with the supplier to get the best deals and terms.

Where to Buy

You can source diamond polishing pads from various suppliers, including specialized polishing pad manufacturers and online marketplaces. Look for suppliers that offer a range of products, good customer service, and reliable shipping.

Final Thoughts

Selecting the right diamond polishing pad involves understanding your specific needs, evaluating different types and features, and considering factors such as surface type and pad durability. By delving into these aspects, you can make an informed choice that will enhance your polishing projects and deliver the ultimate finish.

Armed with this guide, you’re ready to navigate the world of diamond polishing pads with confidence. Whether you’re a DIY enthusiast or a professional in the industry, the right pads will make all the difference in achieving a flawless result.