Extending the Lifespan of Your Diamond Polishing Tools

When it comes to maintaining the quality and efficiency of your diamond polishing tools, a proactive approach can significantly extend their lifespan. For professionals in the industry, whether you’re a wholesaler, retailer, or end-user, knowing how to care for and maintain these essential tools is crucial. This guide will provide you with practical tips and insights to ensure your diamond polishing pads and related tools perform at their best for as long as possible.

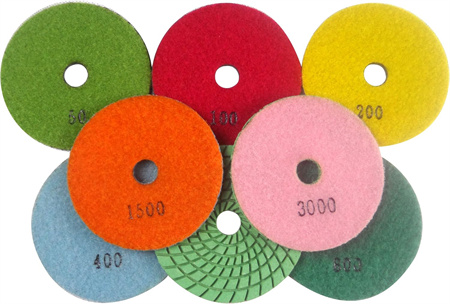

1. Understanding Your Diamond Polishing Tools

2. Proper Usage Techniques

One of the most effective ways to extend the lifespan of your diamond polishing tools is by using them correctly. Always ensure that the tool is suited for the specific job and material. Overloading the tool or using it on inappropriate surfaces can lead to premature wear and tear. For diamond polishing pads, use them according to the recommended speed and pressure guidelines. Excessive pressure can cause the diamond segments to wear down faster, reducing the tool’s effectiveness.

3. Regular Cleaning

Cleaning your diamond polishing tools after each use is essential. Accumulated residue can affect the tool’s performance and lead to uneven results. For diamond polishing pads, use a soft brush or compressed air to remove debris. For more thorough cleaning, you can rinse the pads with water and allow them to dry completely before storage. Avoid using harsh chemicals that might damage the tool’s surface or compromise its integrity.

4. Proper Storage

Storing your diamond polishing tools properly can significantly impact their longevity. Ensure that the tools are kept in a dry, cool place to prevent moisture-related issues such as rust or corrosion. For diamond polishing pads, it’s best to store them flat and avoid stacking them to prevent deformities. Using protective covers or cases can also help keep the tools free from dust and damage.

5. Regular Inspection and Maintenance

Routine inspections of your diamond polishing tools can help identify potential issues before they become significant problems. Check for signs of wear, such as uneven diamond distribution or loss of abrasive material. For diamond grinding wheels and discs, ensure that they are properly balanced and that there are no visible cracks or damage. Regular maintenance, such as dressing the diamond surface or replacing worn-out pads, will keep your tools in optimal condition.

6. Choosing Quality Products

Investing in high-quality diamond polishing tools can make a significant difference in their durability and performance. When selecting tools, consider reputable manufacturers and suppliers known for their quality products. For those in the wholesale or retail sector, partnering with reliable suppliers who offer high-grade diamond tools will not only benefit your business but also ensure customer satisfaction.

7. Understanding the Importance of Diamond Quality

The quality of the diamonds used in polishing pads and tools can affect their performance and lifespan. Higher-quality diamonds are more durable and provide better results over time. When purchasing diamond polishing tools, pay attention to the grade and quality of the diamonds used. This can help you make informed decisions and choose products that offer superior longevity and efficiency.

8. Addressing Common Issues

Even with proper care, diamond polishing tools may encounter issues. For instance, if you notice that your diamond polishing pad is not delivering the desired finish, it might be due to clogged or worn-out diamonds. In such cases, cleaning or replacing the pad can resolve the issue. For more complex problems, consulting with a professional or the tool manufacturer can provide guidance and solutions.

9. Keeping Up with Industry Trends

The diamond polishing tool industry is constantly evolving, with new technologies and innovations emerging regularly. Staying informed about industry trends and advancements can help you choose the most effective tools and techniques for your needs. For professionals, attending trade shows, reading industry publications, and engaging with manufacturers can provide valuable insights and updates.

In conclusion, extending the lifespan of your diamond polishing tools involves a combination of proper usage, regular maintenance, and informed purchasing decisions. By understanding the specific needs of your tools and following best practices for care and storage, you can ensure that they continue to perform efficiently and deliver exceptional results. For businesses, investing in high-quality products and maintaining a strong relationship with reliable suppliers will contribute to long-term success and customer satisfaction in the diamond polishing industry.