Everything You Need to Know About OEM Diamond Pads

When it comes to achieving the perfect finish on surfaces, diamond polishing pads are indispensable. These pads, often crafted by OEM (Original Equipment Manufacturer) suppliers, are renowned for their durability and effectiveness in polishing various materials. This guide will delve into everything you need to know about OEM diamond pads, covering their benefits, applications, and key considerations for buyers.

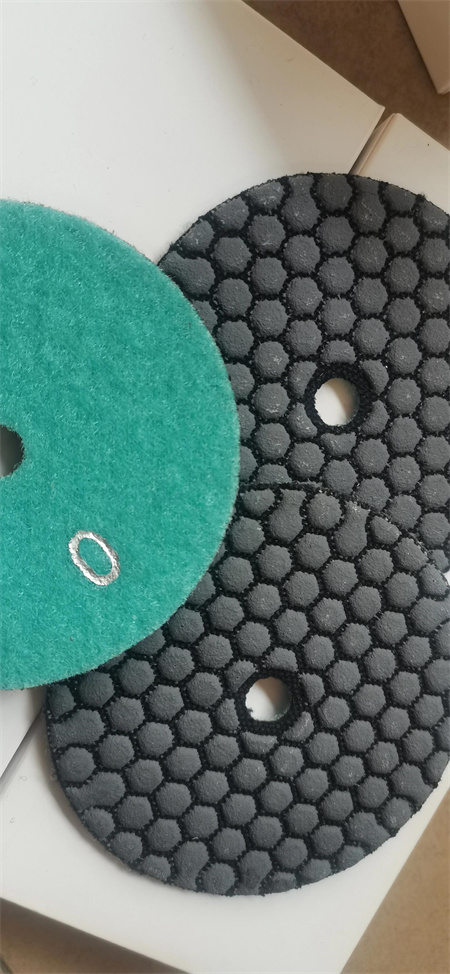

Understanding OEM Diamond Pads

OEM diamond pads are high-quality polishing tools made by manufacturers who supply directly to other brands. These pads are embedded with industrial-grade diamonds, making them highly effective at grinding and polishing surfaces. The ultimate goal of these pads is to provide a smooth, polished finish on materials like concrete, granite, marble, and even glass.

Why Choose OEM Diamond Pads?

Opting for OEM diamond pads comes with numerous advantages. Firstly, these pads are designed to meet rigorous standards, ensuring that they deliver consistent performance and durability. Unlike generic pads, OEM diamond pads often come with a guarantee of superior quality and craftsmanship. They are engineered to work seamlessly with specific machinery, providing optimal results with less effort.

Applications of Diamond Polishing Pads

Diamond polishing pads have versatile applications. They are commonly used in the construction and renovation industries for polishing concrete floors, countertops, and walls. Additionally, they are essential in the stone industry for finishing granite and marble surfaces. In the automotive and aerospace sectors, these pads are used to achieve high-gloss finishes on various components.

Key Considerations When Buying OEM Diamond Pads

1. Material Compatibility: Ensure that the diamond pads you choose are compatible with the material you intend to polish. Different pads are designed for different surfaces, and using the wrong type can affect the quality of the finish.

2. Pad Grit: Diamond pads come in various grits, from coarse to fine. Coarser pads are used for heavy grinding, while finer pads are used for finishing and achieving a high-gloss shine. Choosing the right grit is crucial for achieving the desired outcome.

3. Pad Size and Shape: Depending on your machine and the surface area you need to polish, you may require pads in different sizes and shapes. Ensure that the pads you select fit your equipment and meet your specific needs.

4. Durability and Longevity: The lifespan of diamond pads can vary based on their quality and the intensity of use. Opt for pads made from high-quality materials to ensure they last longer and perform better.

5. Cost and Value: While OEM diamond pads may come at a higher price compared to generic options, they often provide better performance and longevity. Consider the value they offer in terms of efficiency and durability.

When sourcing OEM diamond pads, it’s essential to find a reliable manufacturer. Look for suppliers with a strong track record in the industry and positive reviews from previous clients. Reputable suppliers should provide detailed product specifications and be transparent about their manufacturing processes.

Keywords for SEO Optimization

– OEM diamond pads

– Diamond polishing pads

– Diamond polishing pad suppliers

– Diamond pad manufacturer

– Concrete polishing pads

– Granite polishing pads

– Marble polishing pads

– Industrial diamond pads

– Diamond abrasives

– Polishing tools

In summary, OEM diamond pads are a crucial tool for achieving high-quality finishes across various applications. By understanding their benefits, applications, and key considerations, you can make informed decisions and choose the best products for your needs. Whether you are a wholesaler, retailer, or end-user, selecting the right diamond pads will ultimately contribute to superior polishing results and enhanced surface quality.