How to Avoid Surface Damage When Polishing with Diamond Pads

Polishing surfaces to a mirror-like shine is both an art and a science, particularly when using diamond polishing pads. As experts in this field, we understand the intricacies involved in achieving the ultimate finish without causing damage. Here’s how to navigate this process effectively.

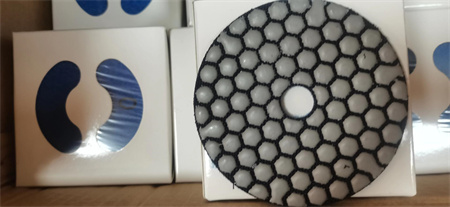

Selecting the appropriate diamond pad is crucial. Diamond polishing pads come in various grits, from coarse to fine, designed for different stages of the polishing process. For initial grinding, a coarse pad is ideal, but for the final, high-gloss finish, a finer pad is necessary. Ensure you’re using a pad that matches your surface material—whether granite, marble, concrete, or another type.

2. Use Proper Technique

The technique you use can make or break the final result. Always start with a clean surface to avoid introducing debris that can scratch the material. When polishing, apply even pressure across the pad. Avoid excessive force, as this can generate heat and cause damage. Instead, let the diamond pads do the work. Keep the pad moving in a consistent pattern to ensure uniform results.

3. Maintain the Right Speed

Operating your polishing tool at the correct speed is essential. Too high a speed can overheat the surface, leading to burns or discoloration, while too low a speed might not achieve the desired finish. Typically, a moderate speed is best, but always refer to the manufacturer’s recommendations for your specific diamond pad and surface.

4. Monitor the Surface Temperature

Overheating is a common cause of surface damage. Monitor the surface temperature during polishing. If you notice excessive heat, it’s time to take a break or switch to a cooling method. Using water or a dedicated cooling solution can help maintain an optimal temperature and prevent damage.

5. Regularly Inspect Your Diamond Pads

6. Use Appropriate Backing Pads

The backing pad you use also affects the outcome. Ensure it is compatible with your diamond pad and surface type. A well-matched backing pad helps distribute pressure evenly and minimizes the risk of damage.

Dust and debris can cause scratches if not properly managed. Regularly clean both the surface you’re polishing and the diamond pads. This simple step helps maintain the quality of your work and prolongs the life of your tools.

8. Know Your Surface Material

Different materials react differently to polishing. For instance, softer materials like marble require less aggressive pads compared to harder materials like granite. Understand the properties of your surface material to select the appropriate pads and techniques.

9. Follow Manufacturer Instructions

Always adhere to the manufacturer’s guidelines for both the diamond pads and the polishing equipment. These instructions are designed to optimize performance and prevent damage, ensuring you achieve the best possible finish.

10. Practice Patience

Polishing is a meticulous process that requires patience. Rushing through it can lead to mistakes and surface damage. Take your time to achieve the desired results, making sure every step is performed correctly.

In summary, avoiding surface damage when using diamond polishing pads involves selecting the right tools, employing proper techniques, maintaining the correct speed and temperature, and ensuring regular maintenance of your equipment. By following these guidelines, you can achieve a flawless, high-gloss finish while preserving the integrity of your surfaces.

For more detailed information on diamond polishing pads and their applications, visit our website or contact us directly. We’re here to help you achieve the ultimate polish with the highest quality products and expert advice.