A Comparative Review of Diamond Pads for Stone and Concrete

When it comes to achieving a flawless finish on stone and concrete surfaces, diamond polishing pads stand out as the ultimate tool. These pads, crafted from high-quality diamond segments, are engineered to deliver precision and durability. For professionals in the industry, understanding the nuances between different diamond pads can make a significant difference. Let’s delve into a comparative review of diamond pads tailored for stone and concrete, focusing on key aspects that influence their performance.

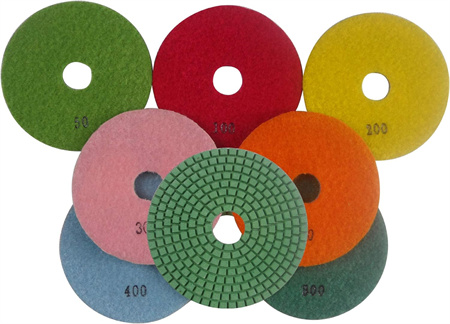

Stone surfaces, including granite, marble, and limestone, require specific polishing techniques to maintain their natural beauty. Diamond pads designed for stone are usually softer and more flexible compared to their concrete counterparts. This flexibility allows them to adapt to the stone’s natural contours, ensuring an even finish. These pads typically feature a higher diamond concentration, which enhances their cutting ability and longevity. For stone applications, look for pads with a lower grit number for initial grinding and higher grits for finer polishing. Brands like [Your Company Name] offer a range of stone polishing pads that meet these requirements, providing high-quality finishes for various stone types.

Diamond Pads for Concrete: Key Characteristics

Comparative Factors: Performance and Durability

When comparing diamond pads for stone and concrete, several factors come into play. Firstly, the grit level plays a crucial role. Stone pads generally start with a finer grit to ensure a smooth finish, while concrete pads begin with coarser grits to handle the rough surface. Secondly, the diamond concentration affects the pad’s lifespan and performance. Higher diamond content in stone pads ensures a more refined finish, while concrete pads with robust diamond segments are built for durability under high-pressure conditions.

Cost and Value

Applications and Use Cases

Diamond polishing pads are versatile tools used in a variety of applications. For stone surfaces, they are commonly employed in residential settings, such as kitchen countertops and bathroom tiles, where a high shine and smooth finish are desired. In contrast, concrete pads are often used in commercial environments like warehouses, showrooms, and large-scale flooring projects where durability and a high-gloss finish are essential. Understanding the specific needs of your project will help in selecting the appropriate type of diamond pad.

Choosing the Right Supplier

When sourcing diamond polishing pads, it’s crucial to partner with a reputable supplier. [Your Company Name] offers a wide range of diamond pads for both stone and concrete, ensuring that you receive high-quality products suited to your specific needs. As an established manufacturer in China, we pride ourselves on delivering durable and efficient polishing solutions for various applications. Our products are crafted with precision, and our team is dedicated to providing exceptional customer service.

Conclusion

In summary, selecting the right diamond polishing pad for stone or concrete involves understanding the specific requirements of each surface. Stone pads are designed for flexibility and a refined finish, while concrete pads are built for durability and heavy use. By considering factors such as grit level, diamond concentration, and cost, professionals can make informed decisions that enhance the quality of their work. Partnering with a reliable supplier like [Your Company Name] ensures access to top-notch products that meet industry standards and exceed expectations.