The Role of Diamond Pads in Restoring Historical Buildings

Restoring historical buildings is akin to breathing life back into the past. Every detail matters, from the choice of materials to the methods used. One crucial element in this delicate process is the use of diamond pads. These versatile tools play a significant role in preserving and enhancing the beauty of our architectural heritage. As a leading manufacturer of diamond polishing pads, we understand their importance in this field and how they contribute to the meticulous work involved in restoration projects.

Diamond pads, with their exceptional hardness and durability, are indispensable in the restoration industry. Unlike traditional abrasives, diamond pads are designed to handle the most challenging surfaces, including those found in historic buildings. The process of restoring a historical building often involves working with various types of stone and masonry, each with its unique characteristics and requirements. Diamond polishing pads are engineered to meet these demands, offering a high level of precision and effectiveness.

One of the primary advantages of diamond pads is their ability to restore the original appearance of surfaces. Over time, historical buildings can suffer from wear and tear, resulting in scratches, stains, and general deterioration. Diamond pads help to address these issues by grinding and polishing surfaces to remove imperfections and reveal the underlying beauty of the material. This is especially important in historical buildings, where maintaining the original aesthetic is crucial for preserving cultural and historical value.

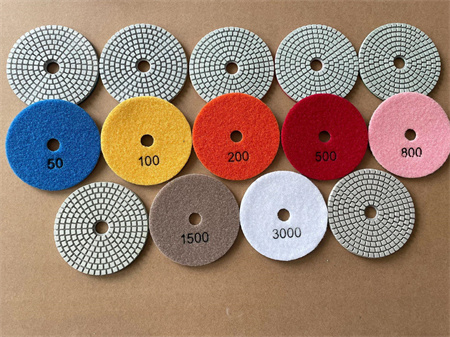

Diamond pads come in various types, each suited for different applications. For example, wet diamond pads are ideal for working on marble and granite surfaces, providing a smooth finish while minimizing dust. Dry diamond pads, on the other hand, are perfect for quick touch-ups and working in areas where water use is limited. By choosing the right type of diamond pad, restoration professionals can achieve optimal results and ensure the longevity of their work.

The versatility of diamond pads extends beyond just polishing. They are also used for surface preparation, such as grinding and honing. Before a surface can be polished to perfection, it often needs to be prepared by removing old coatings, repairing damage, or leveling uneven areas. Diamond pads excel in these tasks, thanks to their ability to effectively cut through tough materials. This preparation is essential for achieving a flawless finish and ensuring that the restored surfaces remain durable and attractive.

As a manufacturer based in China, we take pride in producing diamond polishing pads that meet the highest standards of quality and performance. Our products are designed with the needs of restoration professionals in mind, offering reliability and precision for every project. We cater to a global market, providing bulk orders to importers, wholesalers, and retailers around the world. Our commitment to excellence ensures that our diamond pads are trusted by professionals for their most challenging restoration tasks.

The importance of diamond pads in restoring historical buildings cannot be overstated. They are essential tools for maintaining the integrity and beauty of our architectural heritage. By providing effective solutions for polishing, grinding, and surface preparation, diamond pads play a crucial role in preserving the past while preparing these buildings for the future.