Top Polishing Pads for DIY Projects vs. Commercial Use

When it comes to polishing surfaces, the type of polishing pad you choose can significantly impact your results. For both DIY enthusiasts and commercial operations, selecting the right pad is crucial. Let’s explore the differences between polishing pads suited for DIY projects and those designed for commercial use.

For DIY projects, polishing pads are typically designed to be user-friendly and versatile. These pads are often made from materials that balance ease of use with effective polishing. Here are some features you might find in DIY polishing pads:

1. Ease of Handling: DIY pads are generally lighter and more manageable. They are often designed to be compatible with standard household tools, making them ideal for occasional use.

2. Affordability: Budget is usually a consideration for DIY enthusiasts. Therefore, these pads are often priced lower, providing a cost-effective solution for small-scale projects.

3. Versatility: DIY pads come in various grits and materials to accommodate different tasks, from buffing up a car’s paint to shining up granite countertops.

4. Convenience: Many DIY pads are designed for ease of attachment and removal, making the process less cumbersome.

Commercial Polishing Pads

Commercial polishing pads, on the other hand, are engineered for durability and high performance in professional settings. Here’s what you need to know about commercial polishing pads:

2. Specialization: Commercial pads often come in a range of specific designs tailored to particular surfaces or materials, including concrete, marble, and granite. This specialization helps achieve a superior finish.

3. High Efficiency: Designed for frequent use, these pads offer faster and more efficient polishing, reducing the time and effort needed for large-scale projects.

4. Cost: While generally more expensive, commercial polishing pads provide higher performance and durability, which can translate to better long-term value for businesses.

Key Considerations for Both

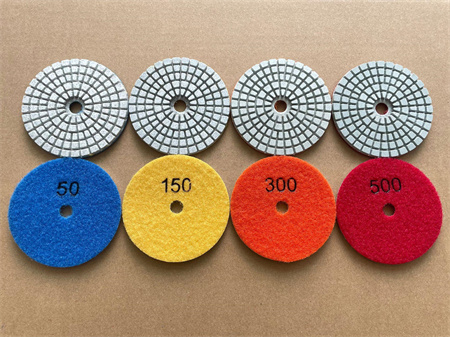

1. Material Composition: Diamond polishing pads are renowned for their effectiveness, particularly for hard surfaces. They are a popular choice for both DIY and commercial use, but the quality and formulation can vary.

2. Grit Levels: Both DIY and commercial pads come in various grit levels. For a smooth finish, a finer grit is essential, while a coarser grit is used for initial sanding and material removal.

3. Attachment Mechanisms: Look for pads that offer secure attachment methods, whether you’re using them with a household drill or a professional-grade polishing machine.

4. Application: Whether you are polishing a car, floor tiles, or a countertop, ensure the pad is designed for the material you are working on.

Conclusion

Choosing the right polishing pad depends on your specific needs. For DIY projects, ease of use and affordability are key, while commercial use demands durability and efficiency. By understanding these differences and considering factors such as material composition and grit levels, you can select the ideal polishing pad for your project or business.

Remember, investing in high-quality pads, especially those with diamond or ceramic components, can make a significant difference in achieving the ultimate polished finish. For those seeking reliable suppliers, exploring options from reputable manufacturers can ensure you get the best products for your needs.