How to Avoid Contamination When Using Diamond Pads

When working with diamond pads, maintaining a clean and controlled environment is essential to achieving high-quality results and prolonging the lifespan of your equipment. Whether you’re polishing concrete, granite, or other materials, contamination can easily occur, leading to surface defects and reduced efficiency. But don’t worry – avoiding contamination is simpler than it sounds. Let’s explore some key strategies to keep your diamond pads in top condition and prevent contaminants from interfering with your work.

The first step in avoiding contamination starts before you even begin using your diamond pads. It’s crucial to inspect the surface you’re working on thoroughly. Any dirt, dust, or debris can transfer onto the diamond pad, causing imperfections on the polished surface. You should clean the area properly before starting. A quick sweep with a vacuum or a mop can make a significant difference. If you’re working with concrete or stone, consider using a degreaser or a mild detergent to remove any oils or grime that could cause the diamond pad to slip or wear unevenly.

Another effective strategy is to monitor the environment in which you’re working. When you’re using diamond pads, a clean workspace is essential. Airborne dust or dirt can quickly land on the surface of your pads, potentially scratching or damaging the material you’re polishing. You can minimize airborne contaminants by using fans, dust extractors, or even a tarp to cover your work area when possible. This might seem like an extra effort, but it goes a long way in preventing problems down the line.

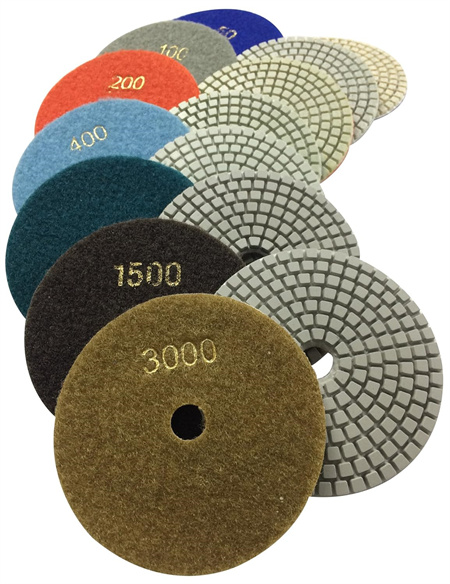

In some cases, contamination may arise from using improper tools or the wrong type of diamond pad for a particular material. If you use the same pad on multiple materials without cleaning it thoroughly in between, you risk transferring contaminants from one material to another. For example, if you’re polishing concrete after stone and don’t clean the pad properly, the residual material from the stone can transfer onto the concrete surface, leading to stains or uneven finishes. Having dedicated pads for specific materials and keeping them clean between uses can eliminate this risk.

Even the way you handle your diamond pads matters. Oils from your hands, dust from your clothes, and any other contaminants you might carry can easily transfer to the pad. It’s a good idea to wear gloves when handling your diamond pads and avoid touching the working surface of the pad. If you accidentally touch the pad with your hands, give it a quick rinse to prevent oils or dirt from affecting its performance.

Lastly, if you’re working in a highly regulated environment or dealing with particularly sensitive materials, such as those requiring food-grade finishes, it’s crucial to follow specific contamination control procedures. In such cases, consider using dedicated, clean-room facilities or adhering to industry-specific guidelines to prevent contamination. This may involve using special containment equipment, ensuring air filtration, or even wearing protective suits to guarantee a contaminant-free result.

By staying mindful of these factors, you can avoid the common pitfalls that lead to contamination when using diamond pads. Whether you’re a seasoned professional or a DIY enthusiast, taking the time to prepare your workspace, maintain your pads, and stay conscious of the environment can make all the difference in the quality of your finish. Not only will this help you achieve a flawless surface, but it will also ensure that your diamond pads perform at their best for years to come.