Using Diamond Pads for Stone Countertop Polishing

When it comes to achieving a flawless shine on your stone countertops, diamond polishing pads are the ultimate tool in your arsenal. Whether you’re a wholesaler, retailer, or end-user looking for top-notch results, understanding the benefits and techniques of using diamond pads can elevate your stone maintenance game to a professional level.

Diamond polishing pads are specifically designed to tackle the tough job of polishing natural and engineered stone surfaces. These pads utilize the unique properties of diamond abrasives, known for their exceptional hardness and durability, to deliver a high-gloss finish that’s hard to achieve with traditional methods. The ultimate goal here is to restore the stone’s original luster, remove scratches, and enhance its overall appearance.

Why Choose Diamond Pads?

The versatility of diamond pads is another major advantage. They are suitable for both wet and dry polishing, giving users flexibility based on their specific needs and preferences. Wet polishing, for instance, helps in cooling the surface and reducing dust, which is ideal for high-performance results. Dry polishing, on the other hand, offers convenience and is useful in areas where water usage is a concern.

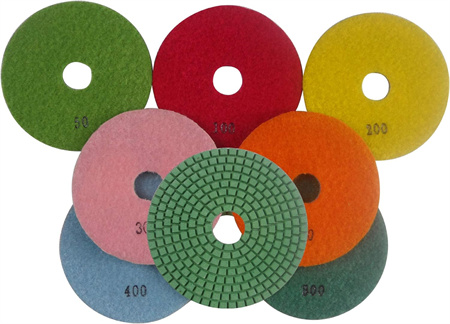

Key Types of Diamond Polishing Pads

1. Wet Polishing Pads: These are designed for use with water, which helps in cooling the surface and minimizing dust. They are perfect for achieving a high gloss on granite and marble countertops.

2. Dry Polishing Pads: These pads are ideal for situations where water is not an option. They are effective for quick touch-ups and are often used in commercial settings.

3. Resin-Bonded Pads: Known for their flexibility and consistency, these pads are used for the final polishing stages, providing a smooth, high-gloss finish.

4. Metal-Bonded Pads: These are more aggressive and are used for initial grinding and shaping of the stone before moving on to finer grits.

Application Tips

To get the best results from your diamond polishing pads, it’s essential to follow a few key tips. Begin with a thorough cleaning of the stone surface to remove any debris or contaminants. For wet polishing, ensure that you have a steady flow of water to keep the surface cool and to wash away any dust and residue. When using dry pads, work in a well-ventilated area to manage dust effectively.

It’s also crucial to match the pad’s grit level to the condition of the stone. Start with a coarser grit if there are significant scratches or imperfections and gradually move to finer grits for a smooth finish. Always follow the manufacturer’s instructions for pad usage to ensure optimal performance and longevity.

Choosing the Right Supplier

When sourcing diamond polishing pads, it’s important to select a reputable manufacturer that provides high-quality products. As a leading diamond polishing pad manufacturer based in China, we offer a range of options that cater to different needs and applications. Our pads are crafted with precision, ensuring durability and effectiveness for all types of stone surfaces.

For wholesale and bulk purchasing, consider factors such as product consistency, customer support, and delivery terms. Working with a trusted supplier can make a significant difference in maintaining the quality and efficiency of your polishing operations.

Conclusion

Diamond polishing pads are an indispensable tool for anyone involved in stone countertop maintenance and restoration. Their superior cutting ability, versatility, and ability to deliver a high-gloss finish make them the ultimate choice for both professionals and DIY enthusiasts. By understanding the various types of pads and their applications, you can achieve remarkable results and ensure that your stone surfaces maintain their stunning appearance for years to come.

For more information on our diamond polishing pads and how they can benefit your business, don’t hesitate to reach out. We are committed to providing top-quality products and exceptional service to meet your specific needs.