The Impact of Grit Variation in Professional Stone Polishing

Stone polishing is an art, one that requires both precision and patience. Whether it’s for a gleaming marble countertop or a beautifully polished granite floor, the key to achieving that perfect finish lies in the skillful use of abrasives. Among the many variables that can influence the final result, grit variation plays a pivotal role. From rough surface to smooth, lustrous shine, understanding how different grits affect the polishing process can make all the difference in achieving professional-quality results.

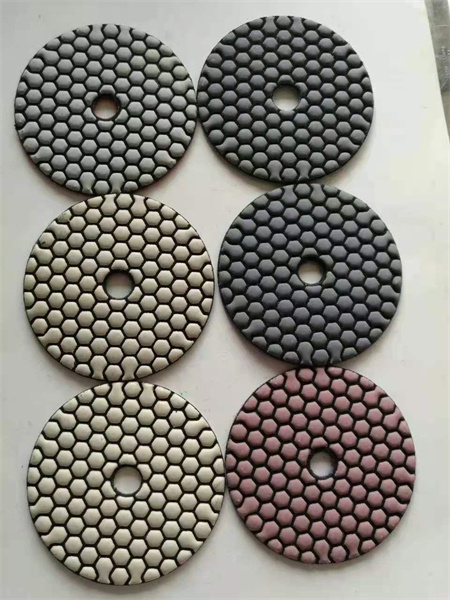

At the heart of stone polishing lies a range of abrasive materials, each with a specific grit size. Grit refers to the coarseness or fineness of the abrasive particles, and it plays a critical role in determining both the texture and finish of the stone. The most commonly used grits are measured on a scale, with lower numbers indicating rougher, more aggressive abrasives and higher numbers representing finer, smoother abrasives.

When starting with rough stone, the initial grinding phase requires the use of a low-grit abrasive, typically between 30 and 50. These grits are designed to remove large imperfections, scratches, and stains from the surface of the stone. At this stage, the primary goal is not to achieve a glossy finish but to level the surface and eliminate any visible flaws. This is a critical phase, as the success of the next polishing steps depends on how well the surface has been prepared.

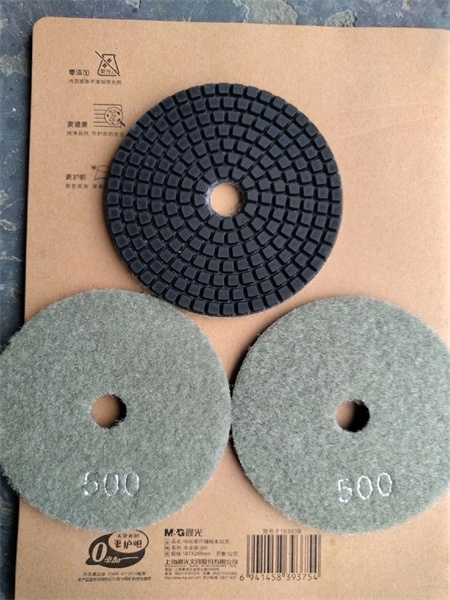

As the process progresses, polishing professionals will gradually move to higher grit abrasives, often shifting to medium grit sizes, such as 100 to 400. This mid-range grit helps to refine the stone surface by smoothing out the deeper scratches left by the coarser abrasives. It’s during this phase that the stone begins to take shape—small imperfections are removed, and the stone’s natural colors start to emerge more clearly. But despite the improvements in texture, the stone is still far from its final polished state.

The true magic happens when higher grit sizes—800, 1500, or even 3000—are used. These finer abrasives are responsible for creating the smooth, glossy finish that is synonymous with professional stone polishing. The finer the grit, the less abrasive the particles, which allows for a gradual buildup of luster without damaging the surface. At this stage, the surface becomes almost mirror-like, with light reflecting off the stone in a uniform, dazzling way. These fine grits don’t just remove surface-level imperfections—they also smooth out microscopic flaws, leading to a highly refined and durable finish.

However, the impact of grit variation isn’t purely aesthetic. It also has practical implications, particularly in terms of longevity and maintenance. A stone surface polished with finer grits tends to be more resistant to staining, scratching, and other forms of damage. The smoother the surface, the harder it is for dirt, oils, or liquids to penetrate the stone, making it easier to clean and maintain in the long run. Moreover, a well-polished stone is less prone to the buildup of grime and debris, which can dull its appearance over time.

That said, the application of grit must be carefully controlled. Too aggressive an approach with a coarse grit can damage the stone, creating deep grooves or leaving the surface uneven. Conversely, using too fine a grit early on can lengthen the polishing process unnecessarily, as it will take more time to remove imperfections and prepare the surface adequately for the finer grits that follow. Balancing the use of different grits, and knowing when to transition between them, is an essential skill for any professional stone polisher.