Maintaining Consistent Pressure for Even Polishing

Polishing is more than just a final touch to a project; it’s an art that requires precision, technique, and above all, control. Achieving a smooth, glossy surface or a flawless finish hinges on maintaining consistent pressure throughout the process. Whether you are working with metal, wood, or stone, uneven pressure can result in undesirable marks, uneven textures, and a lackluster appearance. To truly elevate your craftsmanship, understanding how to apply consistent pressure is key to achieving an even, professional finish.

The importance of pressure in polishing lies in its ability to shape the surface being worked on. Too much pressure in one area can cause damage, while too little in another can leave the surface rough or incomplete. The goal is to ensure every inch of the material receives the same attention, with uniform pressure applied across the entire surface. But how can this be accomplished?

The first step is to recognize that every material requires a different touch. For example, when polishing metal, a heavier hand may be necessary in certain areas, especially if you’re dealing with deep scratches or imperfections. However, applying too much force for prolonged periods can cause the metal to overheat or become distorted. On the other hand, when polishing wood, a lighter, more delicate pressure is often needed to avoid gouging or splintering. Stone surfaces present their own set of challenges, as the hardness can vary significantly, requiring the user to adapt their pressure accordingly.

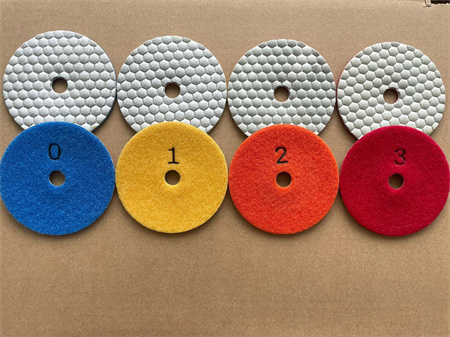

A key factor in achieving consistent pressure is the tool you are using. Whether it’s a rotary polisher, hand sander, or buffing pad, the design of the tool plays a major role in how effectively pressure is applied. If the tool is not ergonomic or well-balanced, it becomes much harder to maintain a steady grip and apply uniform force. Take the time to select equipment that fits comfortably in your hand and is suited to the material you are working with. Many professional polishers also recommend using tools with adjustable speed settings, as controlling the speed allows for a more nuanced application of pressure, especially when transitioning between different areas of the material.

Hand placement is another often-overlooked factor in consistent pressure application. Gripping the tool with both hands and ensuring even force on both sides of the working surface helps to avoid concentrated pressure points that could lead to unsightly defects. It’s easy to fall into the trap of applying pressure with just one hand, which can cause areas of unevenness in the final result. By adjusting your grip and using both hands, you can maintain better control, ensuring that each section of the surface is polished evenly.

In the end, the ultimate goal of polishing is not just about achieving a high shine—it’s about ensuring a balanced, uniform surface that reflects the care and precision you’ve put into the work. Maintaining consistent pressure might sound simple, but it’s a skill that takes time to develop and master. By understanding your material, selecting the right tools, and focusing on technique, you’ll be able to deliver professional-quality results every time.