Speed and Pressure Guidelines for Diamond Pads

When working with diamond polishing pads, understanding the balance between speed and pressure is crucial for achieving optimal results. Whether you’re a wholesaler, importer, or retailer, knowing how to use these pads effectively can enhance your product offerings and satisfy your clients.

Diamond polishing pads are versatile tools used for various applications, from marble and granite to concrete surfaces. The key to using them effectively lies in managing two critical factors: speed and pressure. Let’s delve into these elements to ensure you get the ultimate performance from your diamond pads.

Speed Considerations

The speed at which your polishing pad operates can significantly impact the quality of the finish. For most polishing tasks, a moderate speed is preferred. High-speed operation might seem tempting for faster results, but it often leads to excessive heat and wear on the pad. On the other hand, too slow a speed can prolong the process and reduce efficiency. Generally, a speed range of 2,000 to 4,000 RPM (revolutions per minute) is ideal for diamond polishing pads, depending on the specific material being worked on.

Pressure Guidelines

Pressure is another crucial aspect to manage. Applying too much pressure can cause the diamond pads to wear out quickly and may damage the surface you’re polishing. Conversely, insufficient pressure can result in an uneven finish and extended working times. It’s best to apply moderate, consistent pressure to achieve a smooth, even surface. For optimal results, start with light pressure and gradually increase it as needed, ensuring that the pressure applied does not exceed the pad’s recommended limits.

Choosing the Right Diamond Pad

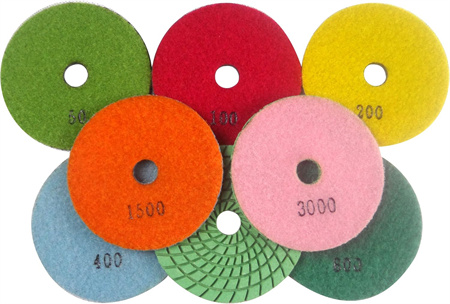

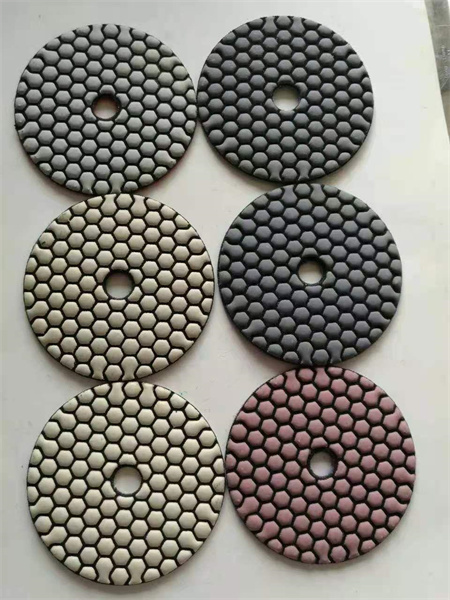

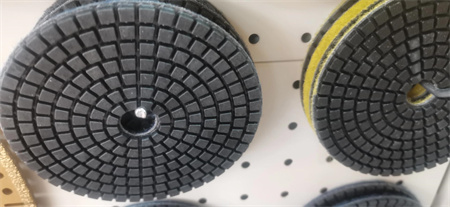

Selecting the appropriate diamond pad for your project is essential. Diamond pads come in various grits and bonding types, each suited for specific tasks and surfaces. Coarse grits are used for heavy grinding and initial polishing, while finer grits are used for final polishing and achieving a high-gloss finish. Ensure that you choose a pad that matches your project’s requirements and material type to achieve the best results.

Applications and Best Practices

Diamond polishing pads are used in a wide range of applications, including floor restoration, countertop finishing, and surface smoothing. For floors, it’s important to follow a systematic approach, starting with coarser grits and progressing to finer ones. In contrast, for countertops or delicate surfaces, a more careful approach with finer grits may be necessary to prevent damage.

When using diamond pads, keep the following best practices in mind:

1. Always follow the manufacturer’s recommendations for speed and pressure settings.

2. Regularly inspect and replace pads to ensure consistent performance.

4. Use appropriate water or lubrication to reduce friction and extend the life of the pad.

Conclusion

Balancing speed and pressure when using diamond polishing pads is key to achieving the ultimate finish and extending the life of your tools. By following the guidelines outlined and selecting the appropriate pads for your needs, you can enhance your polishing process and deliver exceptional results to your customers. Remember, a well-informed approach not only improves the quality of your work but also strengthens your reputation in the industry.