The Role of Water in Wet Polishing Pads

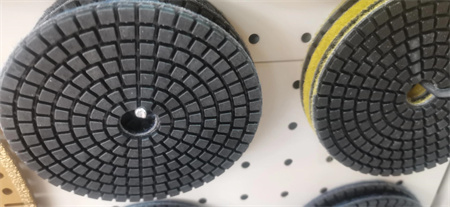

When it comes to achieving that perfect finish on a surface, whether it’s for stone, glass, or concrete, wet polishing has become an essential technique. Central to this process are the polishing pads themselves, which can make or break the quality of the end result. What might be surprising to some is the crucial role that water plays in this process. While water may seem like a simple element, its interaction with polishing pads is far more complex and vital than most realize.

First and foremost, water acts as a coolant. Polishing generates heat, and without a cooling agent, that heat can quickly cause damage to both the surface being worked on and the polishing pad itself. As the pad rotates, friction builds up, and this can lead to thermal buildup. Water helps to dissipate this heat, keeping the temperature under control and preventing excessive wear on the pad and any potential damage to the material. This cooling effect is especially critical when working with harder materials like granite or quartz, where the heat could cause the material to crack or discolor.

In addition to cooling, water serves as a lubricant. The polishing process involves not just friction but also the abrasive elements of the pad making direct contact with the surface. Without lubrication, this direct contact can result in a harsh and uneven finish, potentially damaging the material. Water creates a thin film that reduces friction between the pad and the surface. This smooths out the abrasives, allowing them to glide across the material more evenly and effectively. It helps prevent scratches and swirls, leaving behind a pristine, glossy finish.

Water also plays a key role in cleaning during the polishing process. As the pad works to remove imperfections from the surface, debris like dust, particles, and slurry are created. These can quickly build up and clog the pad, reducing its effectiveness and potentially ruining the surface. Water helps to flush away these particles, keeping the pad clean and ensuring that it remains in contact with the material for longer periods without diminishing its effectiveness. The continuous flow of water prevents slurry from hardening on the pad, keeping the abrasives active and capable of cutting efficiently.

Beyond the mechanical benefits, water is also an environmental asset. Wet polishing pads, when used correctly, can be more environmentally friendly than dry polishing techniques. The absence of airborne dust particles makes it a safer choice for workers, as it reduces the need for protective gear such as respirators. Furthermore, using water allows for the recycling of certain fluids, reducing waste and improving the sustainability of the process.

However, it’s important to note that not all water is created equal when it comes to wet polishing. The quality of the water can affect the outcome of the polishing process. Hard water, for instance, can leave mineral deposits on the surface, which could cause streaks or uneven finishes. It’s crucial to ensure that the water used is clean and free of impurities to maintain the desired quality of the surface.

Water also contributes to the longevity of polishing pads. By preventing the pad from overheating, lubricating it, and keeping it clean, the pad can last longer and perform more effectively over time. This translates into cost savings, as users won’t need to replace pads as frequently, and the process becomes more efficient overall.

In conclusion, while it may seem like a small part of the process, water is integral to the success of wet polishing. From cooling and lubrication to cleaning and environmental considerations, its role is multifaceted and crucial to achieving optimal results. Whether you’re a professional in the field or a DIY enthusiast, understanding and leveraging the power of water in conjunction with polishing pads will ultimately lead to smoother, more beautiful surfaces and longer-lasting equipment.