The Role of Technology in Polishing Pad Innovation

In the world of surface finishing, polishing pads play a crucial role in achieving a smooth, flawless finish. Whether used in automotive detailing, semiconductor manufacturing, or even in the beauty industry, the performance of polishing pads can significantly impact the quality of the final product. Over the years, technological advancements have revolutionized the way these pads are designed, produced, and utilized, paving the way for higher efficiency, better results, and enhanced durability.

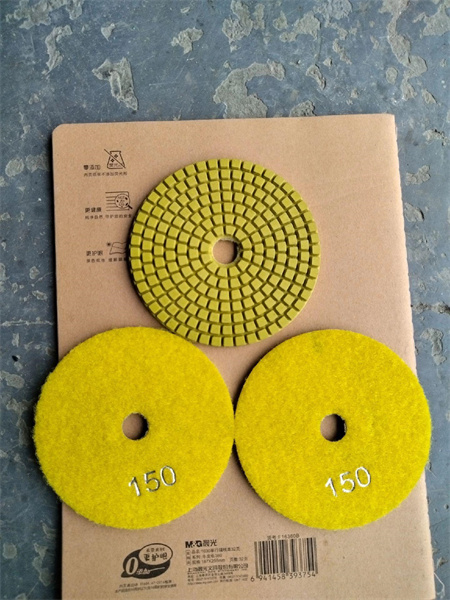

Technology has fundamentally reshaped the manufacturing process of polishing pads. Traditional pads, often made from foam or felt, were once limited in their ability to adapt to different materials or provide consistent performance over time. The introduction of advanced materials, such as microfibers, nanofibers, and composite fabrics, has drastically improved the capabilities of polishing pads. These materials offer increased precision, greater flexibility, and better heat resistance, which are essential for achieving the desired finish without compromising the integrity of the workpiece.

One of the most significant innovations in polishing pad technology has been the development of specialized coatings and surface treatments. These coatings can be engineered to enhance various properties of the pad, such as reducing friction, improving durability, or preventing contamination. For example, the application of hydrophobic coatings can help pads resist moisture, which is particularly useful in automotive and industrial polishing applications where water is often used in conjunction with polishing compounds. Similarly, pads designed with antimicrobial coatings are finding use in environments where hygiene and cleanliness are critical, like medical device manufacturing.

The integration of automation and smart technology has also played a transformative role in polishing pad innovation. By incorporating sensors and intelligent control systems, manufacturers can now monitor and adjust the polishing process in real-time, optimizing the pad’s performance and ensuring that it delivers consistent results. For instance, smart polishing pads are being developed with built-in sensors that can detect changes in pressure, temperature, and vibration. These sensors can communicate with automated polishing machines to adjust the speed, pressure, or pattern of the polish, thus minimizing human error and reducing the likelihood of defects.

The rise of Industry 4.0 has further accelerated the development of high-tech polishing pads. With the advent of connected systems and data analytics, manufacturers can gather vast amounts of data from the polishing process. This data can be used to predict maintenance needs, track performance trends, and even optimize the design of new pads. By leveraging machine learning algorithms, manufacturers can identify the best materials, coatings, and production techniques for specific applications, ensuring that polishing pads are tailored to the exact needs of each job.

In addition to enhancing functionality, technology has also contributed to making polishing pads more sustainable. With increasing concerns over environmental impact, manufacturers are turning to green technologies to reduce waste and improve the sustainability of their products. For example, eco-friendly materials like biodegradable foam and natural fibers are now being used to produce polishing pads that are both effective and environmentally conscious. Moreover, innovations in the production process, such as 3D printing, allow for the creation of pads with complex geometries that optimize material usage and reduce waste during manufacturing.

The role of technology in polishing pad innovation is undeniably transformative. What was once a straightforward tool for surface finishing has evolved into a high-performance, smart solution that adapts to the specific needs of various industries. As technology continues to advance, we can expect polishing pads to become even more efficient, sustainable, and user-friendly. From advanced materials to smart sensors, the future of polishing pads looks bright, with endless possibilities for improving both the process and the results of surface polishing.