Top Diamond Polishing Pads for Granite Polishing

Granite, with its natural beauty and durability, is one of the most popular materials used in countertops, flooring, and various other architectural applications. But to maintain its stunning appearance, polishing is crucial. The right polishing pads make all the difference, especially when it comes to granite. Diamond polishing pads are the go-to choice for many professionals, providing a smooth, high-gloss finish that is both durable and efficient. But with so many options available, how do you choose the best one for your granite polishing needs?

First and foremost, it’s important to understand why diamond polishing pads are superior for granite. The reason lies in the hardness of diamond itself. Granite, being a tough and dense material, requires abrasives that can keep up with its toughness. Traditional polishing pads simply don’t cut it. Diamond pads are designed to work effectively on such hard surfaces, making them ideal for granite and other stone materials.

When it comes to selecting the best diamond polishing pad, several factors come into play—grit levels, the type of bond, the quality of the diamonds used, and the pad’s design. These elements combine to determine the pad’s effectiveness in achieving a flawless finish. Let’s dive into what makes certain diamond polishing pads stand out from the rest.

1. Grit Range and Versatility

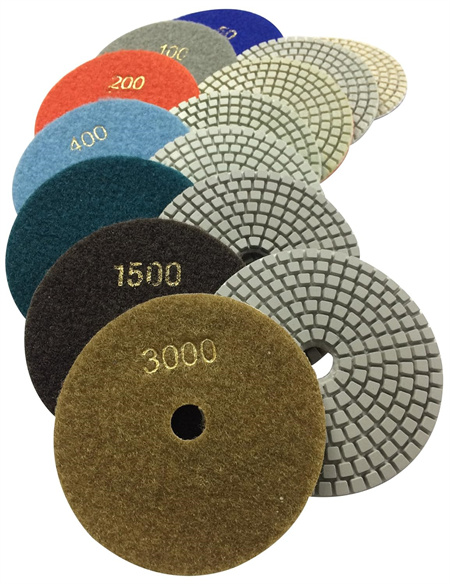

Polishing pads for granite typically come in a wide range of grits, each suited for a specific stage of the polishing process. From the coarse pads (50 or 100 grit) designed for heavy grinding and material removal to the finer pads (3000 grit and above) that produce a high-gloss finish, the right grit is key. A quality set of pads will have a comprehensive grit progression, allowing you to start with the rougher pads for surface prep and finish with the ultra-fine ones for that smooth, glossy shine.

For professional granite polishers, it’s ideal to have a complete grit set on hand. But for those looking for a simpler solution, there are hybrid pads designed to perform multiple tasks with a single pad. These pads can take you from initial grinding all the way to final polishing with minimal changes.

Not all diamonds are created equal, and the same holds true for diamond polishing pads. The quality of diamonds embedded in the pads plays a huge role in determining how well the pad will perform. High-quality diamonds will ensure a more efficient and longer-lasting pad, while lower-grade diamonds may wear down faster and require more frequent replacements.

Top manufacturers of diamond polishing pads use industrial-grade diamonds that are carefully selected for their toughness and ability to hold up under pressure. These diamonds are designed to maintain their sharpness over time, providing consistent results from the beginning to the end of the polishing job.

3. Wet vs. Dry Polishing Pads

Granite polishing can be done either wet or dry, and your choice of polishing pad should match the method you’re using. Wet polishing is the preferred method for granite because it helps to cool down the surface and reduces dust. This makes it easier to achieve a high-quality finish while keeping the workspace clean.

Wet polishing pads are typically more aggressive, cutting through granite more quickly and efficiently. However, dry polishing pads have the advantage of being more convenient for smaller jobs or situations where access to water is limited. Many of the best diamond polishing pads on the market are versatile enough to be used both wet and dry, giving you flexibility depending on your situation.

4. Pad Durability and Longevity

Granite polishing pads can be an investment, and durability matters. High-quality diamond pads are designed to last longer, allowing you to complete several granite surfaces before the pad begins to degrade. The durability of a polishing pad depends on both the type of diamond and the bond used to attach the diamonds to the pad.

Pads with a metal bond tend to last longer than resin-bonded pads, especially for heavy-duty use. Resin-bonded pads, however, offer a finer finish and are ideal for achieving a smooth, shiny surface without leaving scratches or marks. Depending on your needs, you may choose a combination of both types for different stages of the polishing process.

If you’re looking for top-notch diamond polishing pads for granite, several reputable brands consistently deliver high-quality products. Here are some of the best:

– Makita: Known for their robust and durable tools, Makita’s diamond polishing pads are a favorite among professionals. Their pads are engineered for long-lasting performance and are designed to work effectively with both wet and dry polishing methods.

– Diaplus: Diaplus offers a range of diamond pads designed specifically for granite, with a reputation for providing excellent results. Their pads are particularly known for delivering a glossy finish with minimal effort.

– Husqvarna: Husqvarna’s diamond pads are famous for their precision and effectiveness, making them ideal for both commercial and residential granite polishing. They offer various grit sizes, from coarse to ultra-fine, ensuring you can tackle any project.

– Gison: Gison’s diamond polishing pads are highly regarded for their consistent performance and quality. They provide a perfect balance of durability and precision, making them a solid choice for granite polishing.

Final Thoughts

By understanding the intricacies of different polishing pads and how they interact with granite, you can ensure that your granite surfaces maintain their beautiful, polished look for years to come. Whether you’re working on countertops, floors, or any other granite feature, choosing the right pad can elevate your work to a whole new level of perfection.