Tips for Safe Operation When Using Diamond Polishing Pads

Diamond polishing pads are an essential tool for achieving a smooth, glossy finish on a variety of surfaces, including stone, concrete, marble, granite, and more. Whether you’re a professional or a DIY enthusiast, using these pads can make a world of difference in your results. However, with great power comes great responsibility. As effective as they are, diamond polishing pads require careful handling to ensure safety and prevent accidents. Here are some essential tips to help you operate them safely and effectively.

Choose the Right Pad for the Job

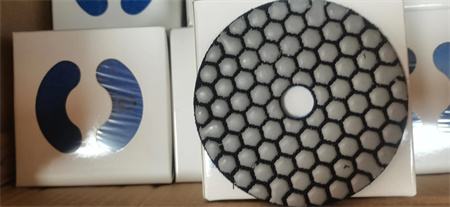

The first step to safe operation begins even before you start polishing. Selecting the correct diamond polishing pad for your project is crucial. Pads come in various grits, from coarse to fine, each suited for different stages of polishing or different materials. For example, rougher grits are typically used for removing scratches and stains, while finer grits are meant for bringing out the shine.

If you’re polishing a delicate surface, make sure to use pads specifically designed for that material. For instance, granite requires a different set of pads compared to concrete. Using the wrong type of pad could lead to damage or suboptimal results. Make sure to check the manufacturer’s guidelines for recommended grit sequences and usage.

Wear Appropriate Personal Protective Equipment (PPE)

When you’re working with diamond polishing pads, safety should always be your top priority. Diamond pads are incredibly effective at what they do, but they can also pose risks if proper precautions aren’t taken. Protective eyewear is a must, as the high-speed rotation can cause debris to fly, which could damage your eyes or skin.

Depending on the environment and the materials you’re working with, wearing gloves, ear protection, and a dust mask may also be necessary. The noise level generated by the polishing machine can be intense, and prolonged exposure to it can harm your hearing. Additionally, some materials, like concrete, may release harmful dust that you should avoid inhaling. Wearing the proper PPE will not only keep you safe but will also improve the overall comfort of the work environment.

Inspect Your Equipment Regularly

Before using your diamond polishing pads, take a moment to inspect both the pads and the polishing machine. A quick inspection can save you from costly accidents. Check for any signs of wear or damage on the pads, such as cracks or frayed edges, which can lead to uneven polishing or breakage during operation.

Similarly, ensure that the polishing machine is in good working order. Look for any loose or damaged parts that could cause the machine to malfunction. A damaged tool not only reduces efficiency but also increases the likelihood of accidents. Taking a few minutes to check your equipment before starting can save you time, effort, and potentially serious injuries down the line.

Maintain Consistent Speed and Pressure

One of the most common mistakes people make when using diamond polishing pads is applying too much pressure or using the machine at excessive speeds. Both of these factors can result in poor polishing results, excessive wear on the pads, or even damage to the surface you’re working on.

Let the machine do the work. You don’t need to push down hard on the polishing pad, as this can cause excessive heat buildup, leading to burn marks or permanent damage to the surface. Similarly, operating the machine at too high of a speed can result in uneven polishing and premature pad wear. Stick to the manufacturer’s recommendations for optimal speed and pressure, and always work slowly to ensure the best results.

Keep the Surface Wet or Lubricated

When using diamond polishing pads on stone or concrete, keeping the surface wet or lubricated is essential for both safety and performance. Polishing dry can generate excessive heat, which not only reduces the lifespan of your pads but also increases the risk of injury. Water or a suitable lubricant helps keep the surface cool and reduces the amount of dust and debris that can fly around.

In addition to improving safety, lubrication helps prevent the pads from clogging, which can negatively affect their performance. If you’re working in an environment where water isn’t available, consider using a polishing pad designed for dry use, but always follow the manufacturer’s instructions to avoid damaging the material.

Avoid Overworking the Material

It’s easy to get caught up in the desire for a perfect finish, but overworking the material can lead to unwanted consequences. Polishing too long or using the wrong grit sequence can cause the surface to lose its luster or even sustain damage. If you’re working with a soft stone like marble, over-polishing can result in scratching or discoloration. On harder surfaces like granite, prolonged polishing can lead to unnecessary wear on your pads.

Take breaks during the polishing process and monitor the results. Frequently check the surface for progress, and stop as soon as you achieve the desired finish. This approach will not only extend the life of your diamond pads but also ensure that you achieve the best possible results without risking damage to the material.

Store Your Pads Properly

When you’re finished with your polishing session, don’t just toss your diamond pads into a corner. Proper storage can extend their lifespan significantly. Keep your pads clean and dry, and store them in a place where they won’t get damaged or contaminated. Avoid leaving them in areas exposed to direct sunlight or extreme temperatures, as this can degrade the material and reduce the effectiveness of the diamonds.

If you’re using a wet polishing pad, make sure it’s thoroughly dried before storing it. Moisture trapped in the pad can lead to mold growth or deterioration of the diamonds, reducing the pad’s performance for future use.

Using diamond polishing pads can be a rewarding experience when done correctly, but safety and preparation are key. By choosing the right pad, wearing appropriate protective gear, maintaining your equipment, and following the best practices for polishing, you can ensure that your project runs smoothly and safely. With the right approach, your surfaces will shine, and your tools will last longer—leaving you with results that are both professional and safe.