Understanding Grit Ranges in Diamond Polishing Pads

When it comes to achieving a flawless finish on stone surfaces, one of the most important tools in your arsenal is the diamond polishing pad. Whether you’re working with granite, marble, concrete, or any other hard surface, the key to a smooth, glossy finish lies in choosing the right grit level. But what exactly does “grit” mean, and how does it affect the polishing process?

Grit refers to the size of the abrasive particles embedded in the polishing pad. This factor plays a crucial role in determining how aggressive or fine the pad will be during use. Essentially, a lower grit number means coarser particles, while higher numbers indicate finer abrasives. Each grit level has a specific function in the polishing sequence, and understanding this can help you achieve the desired outcome efficiently.

Starting with lower grits, typically ranging from 30 to 100, these pads are designed for heavy-duty grinding and initial surface preparation. If you’re working with a rough or uneven surface, a coarse pad will help remove deep scratches, imperfections, and excess material. These pads have large, more aggressive diamond particles that cut through the stone quickly, making them ideal for tasks that require significant material removal. However, the trade-off is that they leave visible marks, so they are not suitable for achieving a polished, high-gloss finish on their own.

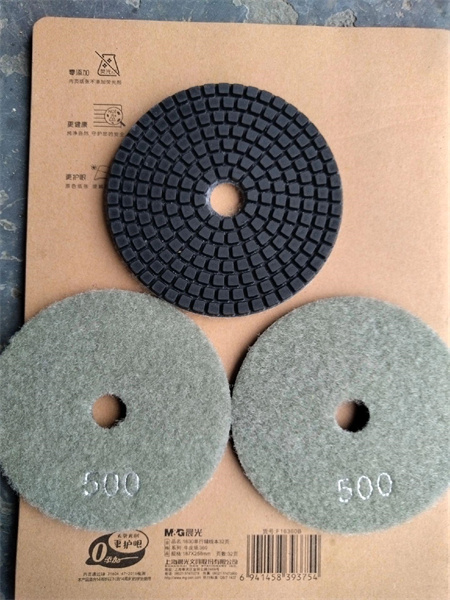

As you progress through the grit range, pads with a grit between 200 and 400 are used for smoothing out the surface after the initial grinding stage. These intermediate pads begin to refine the surface, reducing the visible scratches left by the coarse pads. At this stage, the surface should start to look more even and less rough, but it won’t yet have the shine you’re aiming for.

For that high-gloss, mirror-like finish, you’ll need to use pads with a grit level of 3000, 5000, or even higher. These ultra-fine pads are designed to polish the surface to a high shine, smoothing out any micro scratches and revealing the stone’s natural beauty. The diamond particles in these pads are incredibly fine, meaning they don’t remove much material, but they bring out the shine by polishing the surface to perfection.

Choosing the right grit sequence is crucial for achieving a smooth, shiny finish without unnecessary delays or mistakes. Using a pad that’s too coarse can result in a surface that requires extensive rework, while jumping straight to a fine grit without adequate preparation can lead to an uneven finish.

In addition to the grit level, other factors also influence the performance of diamond polishing pads. The material of the pad itself, the pressure applied during polishing, the speed of the machine, and the type of stone being worked on all play significant roles in the process. For example, harder stones like granite may require more aggressive pads in the early stages, while softer materials like marble can often be polished with finer pads more quickly.

One aspect that is often overlooked is the importance of water or cooling agents during the polishing process. Water helps to reduce friction, prevents overheating of the pads, and ensures that the diamond particles remain effective. It also helps to clear away debris and dust that can interfere with the polishing action, allowing for a cleaner and more even finish.

In conclusion, understanding the different grit ranges in diamond polishing pads is essential for achieving the perfect finish on stone surfaces. By starting with a coarse grit and gradually moving to finer pads, you can remove material efficiently while ensuring that the final result is smooth, glossy, and flawless. Whether you’re a professional working with large surfaces or a DIY enthusiast polishing small stone countertops, knowing how to select and use the right grit range can make all the difference in the outcome of your project.