Latest Innovations in Diamond Polishing Pad Technology

The diamond polishing pad industry is evolving at an unprecedented pace. As manufacturers and end-users alike demand higher performance and efficiency, recent innovations have transformed the landscape of polishing technologies. For importers, wholesalers, and retailers, understanding these advancements can provide a significant edge in the competitive market.

1. Advanced Diamond Grit Composition

One of the most notable innovations in diamond polishing pad technology is the refinement of diamond grit composition. Modern pads now feature enhanced diamond particles that offer superior hardness and durability. These advanced grit compositions enable faster and more efficient polishing, delivering a high-gloss finish with minimal effort. For bulk buyers, this means a longer-lasting product that offers excellent value for money.

2. Improved Resin Bond Formulations

The bonding agents used in diamond polishing pads have seen substantial improvements. Recent advancements in resin formulations have led to pads that are more resistant to heat and wear. This innovation ensures that the pads maintain their effectiveness over longer periods, even under the most demanding conditions. For wholesalers and distributors, this translates to reduced replacement rates and improved customer satisfaction.

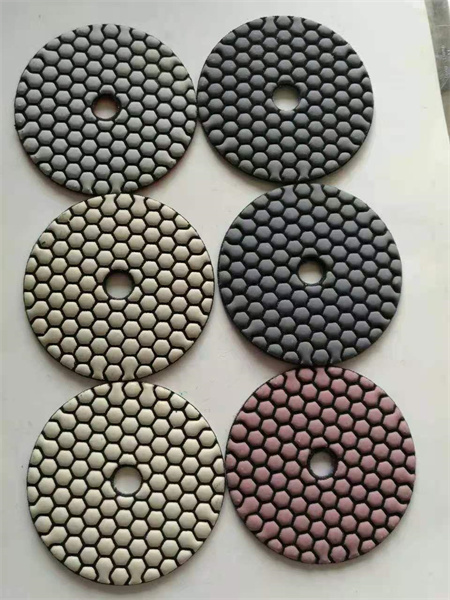

3. Enhanced Flexibility and Versatility

Newer diamond polishing pads offer enhanced flexibility and adaptability to various surfaces. This versatility is achieved through the use of advanced materials that allow the pads to conform to different shapes and textures. As a result, users can achieve a superior finish on a wider range of materials, from concrete to granite. For importers and retailers, this means a broader product offering that can meet diverse customer needs.

4. Environmentally Friendly Solutions

5. Smart Polishing Systems

The integration of smart technology into diamond polishing pads is another groundbreaking development. Modern pads are now equipped with sensors and data analytics capabilities that provide real-time feedback on polishing performance. This technology allows users to optimize their polishing processes and achieve consistent results with greater precision. For wholesalers and importers, these high-tech solutions represent an opportunity to offer cutting-edge products that appeal to tech-savvy customers.

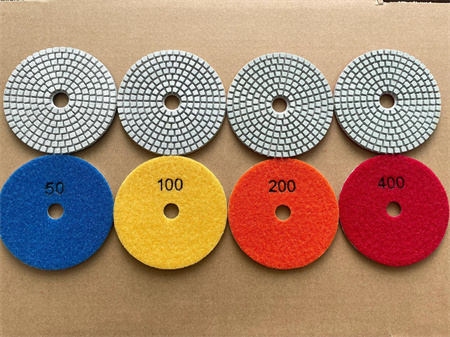

6. Customizable Pad Designs

Customization has become a key trend in the diamond polishing pad industry. Manufacturers now offer pads that can be tailored to specific applications and user preferences. This customization includes options for different sizes, shapes, and abrasive levels, allowing customers to select the perfect pad for their needs. For retailers and wholesalers, this flexibility in product design can help cater to niche markets and specific customer requirements.

7. Increased Efficiency and Cost-Effectiveness

Innovations in manufacturing techniques have also led to more cost-effective production of diamond polishing pads. Advances in automation and material science have streamlined production processes, reducing costs and allowing for more competitive pricing. For importers and distributors, this means access to high-quality products at lower prices, enhancing their ability to offer competitive deals to their customers.