Using Diamond Pads in Large-Scale Stone Restoration Projects

When embarking on a large-scale stone restoration project, selecting the right tools can make all the difference between a job well done and a project fraught with difficulties. Diamond polishing pads are increasingly becoming the tool of choice for professionals in the stone restoration industry, and for good reason. These versatile tools offer exceptional performance, durability, and efficiency, making them ideal for a variety of large-scale applications.

Understanding Diamond Pads

Diamond polishing pads are designed to restore and enhance the appearance of stone surfaces. Unlike traditional polishing pads, diamond pads are embedded with industrial-grade diamond particles that provide a superior cutting and polishing action. These pads are capable of smoothing out rough surfaces, removing scratches, and bringing out the natural shine of stone materials such as granite, marble, and concrete.

Why Choose Diamond Pads for Large-Scale Projects?

1. Efficiency and Speed: In large-scale projects, time is often of the essence. Diamond pads excel in efficiency, allowing you to complete tasks faster compared to conventional methods. Their aggressive cutting action means fewer passes are needed to achieve a high-quality finish, which significantly reduces overall project time.

2. Durability: Large-scale restoration projects require tools that can withstand heavy use. Diamond polishing pads are renowned for their durability and longevity. The diamond particles embedded in the pads resist wear and tear, ensuring that the pads maintain their effectiveness throughout the entire project. This durability translates into cost savings, as fewer pads are needed over time.

Selecting the Right Diamond Pad

Choosing the appropriate diamond pad for your project involves considering several factors:

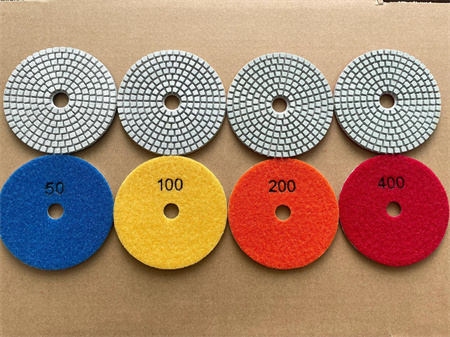

– Grit Size: Diamond pads come in various grit sizes, ranging from coarse to fine. Coarse grits are used for heavy material removal and initial grinding, while finer grits are used for polishing and achieving a high gloss finish. For large-scale projects, a range of grits will likely be needed to progress through different stages of restoration.

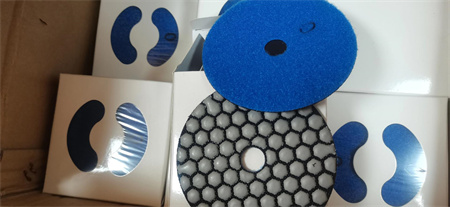

– Backing Material: The backing material of the pad can affect its performance and compatibility with different machines. Backings can be made from various materials such as velcro or resin. Ensure that the backing material matches the requirements of your polishing machine.

– Pad Thickness: Thicker pads are typically used for heavy-duty applications and can provide more cushioning. However, they may be less flexible, which can affect their performance on uneven surfaces. Consider the nature of the stone and the conditions of the project when selecting pad thickness.

Applications in Large-Scale Projects

– Floor Restoration: Diamond pads are ideal for restoring large stone floors, whether in commercial spaces, residential properties, or public buildings. They can effectively remove surface damage and restore the floor’s original shine.

– Countertop Refinishing: For projects involving kitchen or bathroom countertops, diamond pads provide the precision needed to achieve a flawless finish. They are effective in removing scratches and enhancing the appearance of stone surfaces.

– Concrete Surface Polishing: Concrete surfaces, whether in industrial settings or decorative applications, can benefit greatly from diamond pads. These pads are used to smooth out rough concrete and achieve a polished look.

– Monument and Sculpture Restoration: In artistic and historical restoration, diamond pads are used to carefully restore and enhance the details of stone monuments and sculptures. Their ability to provide a detailed and consistent finish is crucial in these sensitive projects.

Conclusion

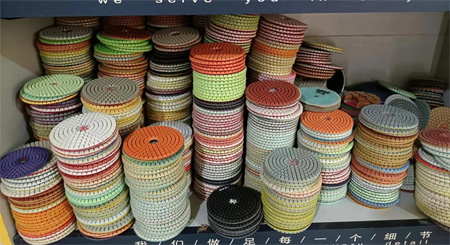

In summary, diamond polishing pads are indispensable tools for large-scale stone restoration projects. Their efficiency, durability, versatility, and ability to deliver consistent results make them an excellent choice for professionals in the industry. Whether you are dealing with floor restoration, countertop refinishing, concrete polishing, or delicate monument restoration, diamond pads offer the performance and reliability needed to achieve outstanding results.

For wholesalers, importers, and retailers in the stone restoration sector, incorporating high-quality diamond pads into your product offerings can significantly enhance your market appeal. As a leading manufacturer in the diamond polishing pad industry, we are committed to providing products that meet the highest standards of performance and quality. Explore our range of diamond pads to find the perfect solution for your large-scale restoration projects and experience the difference that superior technology can make.