How to Source High-Quality Diamond Polishing Tools

Finding the perfect diamond polishing tools for your needs can feel like navigating a labyrinth. Whether you are an importer, wholesaler, or store owner, the quality of the tools you source can significantly impact your business’s success. Here’s a comprehensive guide to help you source high-quality diamond polishing tools, ensuring you get the best products for your clients and operations.

1. Understand the Basics of Diamond Polishing Tools

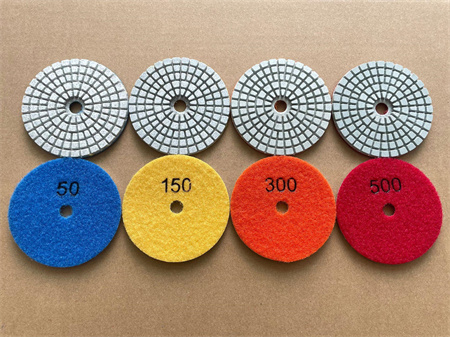

Before diving into sourcing, it’s essential to understand what makes diamond polishing tools high-quality. Diamond polishing tools are used for smoothing and finishing surfaces, typically in industries like construction, automotive, and stone masonry. Key types of these tools include diamond polishing pads, diamond grinding wheels, and diamond abrasive discs.

2. Identify Your Specific Needs

Different applications require different tools. Are you polishing concrete floors, granite countertops, or metal surfaces? Each application demands specific features in a diamond polishing tool. For instance, diamond polishing pads come in various grits and sizes, and selecting the right one depends on whether you need a fine finish or heavy grinding.

3. Research Reputable Manufacturers

To source high-quality diamond polishing tools, start by researching reputable manufacturers. Look for companies with a strong track record in producing reliable, durable products. For instance, manufacturers based in China have a reputation for high-quality diamond polishing pads and other tools. Review their product ranges, manufacturing processes, and customer feedback to gauge their credibility.

4. Verify Product Specifications

When evaluating potential suppliers, closely examine product specifications. High-quality diamond polishing tools should have the following characteristics:

– Durability: Check for the quality of the diamond segments or abrasives. High-grade diamonds and well-bonded segments contribute to longer tool life and better performance.

– Uniformity: Consistency in tool design and performance is crucial for achieving a professional finish.

– Compatibility: Ensure the tools are compatible with your equipment and meet industry standards for safety and efficiency.

5. Assess Manufacturer’s Quality Control

A reliable manufacturer should have stringent quality control measures in place. Request information about their testing procedures and quality assurance practices. Some manufacturers provide certifications or reports that verify their products’ adherence to industry standards. This information can help you avoid sourcing tools that may not meet your quality expectations.

6. Consider Bulk Purchasing and Pricing

For wholesalers and store owners, pricing and bulk purchasing options are significant factors. Many manufacturers offer discounts for bulk orders. Compare prices and terms from different suppliers to find the best deal while ensuring the quality of the tools remains uncompromised. Be cautious of deals that seem too good to be true, as they might indicate subpar products.

Customer feedback can provide valuable insights into the reliability and performance of diamond polishing tools. Look for reviews from other businesses in your industry to understand their experiences with various manufacturers and products. Testimonials can highlight any potential issues or confirm the tools’ effectiveness and durability.

8. Evaluate Supplier Communication and Support

Good communication with your supplier is vital. Choose manufacturers who offer clear and responsive customer service. They should be willing to answer your questions, provide samples, and offer support throughout the purchasing process. Reliable support can make a significant difference, especially if you encounter any issues with your order.

9. Check for Customization Options

Depending on your business needs, you might require customized diamond polishing tools. Some manufacturers offer customization services, allowing you to specify particular sizes, grits, or other features. Custom tools can enhance your product offerings and cater to niche markets.

10. Stay Updated on Industry Trends

The diamond polishing tools industry is continuously evolving with advancements in technology and materials. Stay informed about new trends and innovations to ensure you are offering the latest and most effective tools to your clients. This proactive approach can give you a competitive edge and help you meet the evolving demands of your market.

Conclusion

Sourcing high-quality diamond polishing tools involves thorough research, careful evaluation, and strategic planning. By understanding your needs, researching reputable manufacturers, and considering factors like product specifications and supplier support, you can ensure that you procure tools that enhance your business’s operations and reputation. Remember, the right tools not only improve your product quality but also build trust and satisfaction among your clients.