Diamond Polishing Pads Stone Industry Demand Analysis

The demand for diamond polishing pads in the stone industry has seen remarkable growth in recent years, driven by advancements in both the technology and the need for higher quality finishes. These specialized pads are essential tools for professionals in the stone industry, particularly for those working with granite, marble, and other natural stones. As the demand for luxury and high-end stone products continues to rise, so does the need for efficient, durable, and precise polishing solutions.

The global stone industry, particularly in construction and interior design, has experienced a surge in demand. Architects and designers are increasingly favoring stone materials for their aesthetics, durability, and eco-friendly qualities. In response, stone manufacturers are looking for methods to refine the surfaces of these materials to meet the high standards expected by clients. This is where diamond polishing pads come into play. These pads are designed to provide a smooth, glossy finish without damaging the stone, ensuring that the final product is both visually appealing and long-lasting.

As the stone industry grows, the need for more efficient polishing tools increases. Traditional methods can be time-consuming and labor-intensive, but with diamond polishing pads, the process becomes faster and more consistent. This is particularly important in large-scale production environments where efficiency is crucial to maintaining competitive pricing. The pads are engineered to handle the heavy-duty demands of commercial stone processing, offering long-lasting performance that helps businesses reduce downtime and improve productivity.

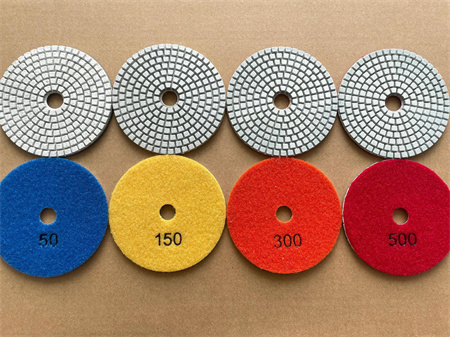

Technology has also played a significant role in shaping the demand for these pads. With the introduction of more advanced diamond materials and cutting-edge manufacturing techniques, the quality and performance of polishing pads have improved significantly. The result is a superior product that offers a better finish, longer lifespan, and improved cost-effectiveness for stone processing companies. Moreover, the customization options available, including different grit sizes and thicknesses, allow businesses to tailor their polishing processes to suit the specific needs of their projects.

Looking ahead, the demand for diamond polishing pads is expected to continue to rise. As the stone industry evolves with new trends and innovations, professionals will continue to rely on high-performance tools like diamond polishing pads to achieve exceptional results. In particular, the growing trend toward sustainable building practices is likely to further fuel the need for high-quality stone products, which in turn will drive the demand for efficient and reliable polishing solutions.

The future of the stone industry depends on continued innovation in tools and materials, and diamond polishing pads are a key component of that evolution. As the industry moves forward, these pads will undoubtedly remain an essential part of stone processing, helping businesses to meet the demands of an ever-changing market while delivering the high-quality finishes that customers expect.