Diamond Polishing Pads Demand in Monument Stone Industry

The demand for diamond polishing pads in the monument stone industry is witnessing an upward surge, driven by the increasing demand for high-quality finishes on stone monuments, tombstones, and memorials. As monument stone production becomes more refined, manufacturers are turning to diamond polishing pads to achieve smooth, glossy finishes that enhance the aesthetic appeal and durability of these products.

In the past, traditional polishing methods often led to inconsistencies in the surface quality, causing a lack of uniformity and limiting the overall visual appeal of the stone. Diamond polishing pads, however, offer a solution to these challenges, delivering exceptional results. Their superior abrasive qualities allow them to smooth rough surfaces more efficiently and effectively, ensuring a flawless finish that can last for years.

The popularity of granite and marble as materials for monuments has also played a crucial role in driving the demand for diamond polishing pads. These hard stones require a higher level of precision and finer abrasives, making diamond polishing pads the ideal choice for stone fabricators looking to produce monuments that are not only durable but visually striking.

Another factor contributing to the rise in demand is the growing trend towards personalized memorials. With families increasingly opting for customized designs, the need for precise, high-quality stonework has never been greater. Diamond polishing pads are essential in achieving the intricate detailing and smooth surfaces required for these personalized touches, from engraved messages to intricate designs.

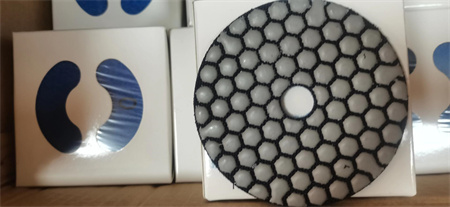

Moreover, advancements in diamond pad technology have improved both performance and cost-effectiveness. Manufacturers now offer a wide range of diamond polishing pads tailored to different stone types and polishing needs, allowing businesses to choose the most suitable products for their specific requirements. This flexibility has made diamond pads more accessible to a broader range of monument stone producers, further boosting their popularity.

The monument stone industry’s shift towards more sophisticated polishing methods reflects broader trends in the construction and design sectors, where quality, durability, and aesthetics are increasingly prioritized. As consumer preferences evolve, so too does the need for polishing solutions that can keep pace with these demands.

In conclusion, the demand for diamond polishing pads in the monument stone industry is poised to continue its growth, fueled by the desire for higher-quality finishes, more personalized memorial products, and the ongoing advancements in polishing technology. For stone manufacturers, investing in these pads is not just a trend; it’s a necessary step in meeting the expectations of today’s market.