Extending the Lifespan of Your Diamond Polishing Tools

Diamond polishing tools are an essential part of many industries, from gemstone cutting to precision manufacturing. Their durability and exceptional performance make them indispensable for achieving a high-quality finish. However, like any tool, they require proper care and maintenance to ensure they continue to function at their best. If you’re looking to maximize the lifespan of your diamond polishing tools and maintain optimal performance, there are several strategies to consider.

The Importance of Cleanliness

A crucial yet often overlooked factor in extending the lifespan of diamond polishing tools is cleanliness. After every use, your tools should be cleaned thoroughly to remove any residue or contaminants that could affect their performance. The buildup of metal dust, abrasives, or polishing compounds can cause the diamond particles on the tool to become clogged, reducing their effectiveness. Using a soft brush or cloth to wipe down the tool and a cleaning solution to remove any stubborn particles can help ensure that the diamonds remain exposed and functional.

Proper Storage

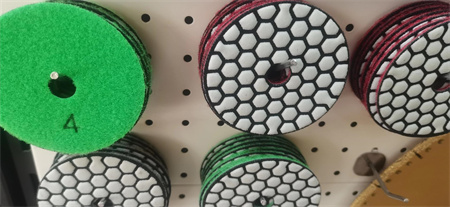

Proper storage is another key factor in maintaining the longevity of your diamond polishing tools. When not in use, these tools should be stored in a dry, dust-free environment. Exposure to moisture or extreme temperatures can degrade the diamonds, causing them to lose their sharpness and cutting ability over time. It’s advisable to store your tools in a protective case or a dedicated drawer where they won’t be exposed to harmful elements or accidental damage.

Using the right kind of storage can also prevent the tools from getting scratched or chipped, as rough handling or contact with other objects can compromise their integrity. Consider using padded compartments or foam inserts that provide cushioning and secure placement for each tool.

Avoiding Overheating

Heat is another enemy of diamond polishing tools. While diamonds are incredibly tough, they are not immune to the effects of excessive heat. Overheating can cause the tool’s diamond particles to lose their edge or even cause the bonding material that holds them in place to break down. This is particularly relevant in high-speed polishing applications, where friction can quickly generate significant heat.

To prevent overheating, it’s essential to monitor the speed and pressure applied during the polishing process. If the tool is running too fast or if too much pressure is being applied, the friction generated will increase the risk of heat buildup. Use variable speed controls if possible, and allow your tools to cool down periodically during use to prevent overheating.

Choosing the Right Polishing Compound

Using the right polishing compound is another way to ensure the longevity of your diamond tools. Compounds that are too abrasive can wear down the diamonds prematurely, while those that are too mild may not provide the desired finish. It’s important to match the polishing compound to the specific material being worked on to prevent unnecessary strain on your tools.

Additionally, always use fresh, high-quality polishing compounds. Old or contaminated compounds can damage both your tools and the materials being polished. Regularly checking and replacing your polishing compounds will help maintain optimal performance and prevent unnecessary tool wear.

Monitoring Tool Wear

While diamond polishing tools are known for their durability, they are not indestructible. Over time, the diamond particles will gradually wear down as they come into contact with hard surfaces. This wear and tear can result in a decrease in polishing efficiency, which is why regular monitoring of your tools is crucial.

Regular Maintenance

Lastly, regular maintenance is essential for keeping your diamond polishing tools in top shape. Depending on the frequency of use, tools should be checked for signs of wear, and the diamonds should be inspected for chipping or dullness. Tools that show signs of damage or degradation should be repaired or replaced promptly to avoid further issues.

In addition to physical maintenance, ensure that the tool is always properly aligned, calibrated, and balanced. Misalignment can lead to uneven wear on the diamonds and can compromise the quality of your work. If you’re unsure of the condition of your tools, seeking professional advice for maintenance or repairs is always a good idea.

Conclusion

Diamond polishing tools are an investment that, when properly cared for, can last for years and continue to deliver superior results. By maintaining a clean work environment, storing tools properly, avoiding overheating, using the correct compounds, and performing regular maintenance, you can significantly extend the lifespan of your tools and keep them working at peak efficiency. A little extra care goes a long way in ensuring that your diamond polishing tools remain as effective and reliable as the day you first used them.