The impact of automation on polishing pad production has significantly reshaped the way manufacturers approach the creation of diamond polishing pads. As technology continues to advance, automation plays an essential role in enhancing productivity, improving quality, and reducing production costs. For companies like ours, which specialize in producing diamond polishing pads and export them globally, automation is not just a trend—it’s a necessity that drives our operations forward.

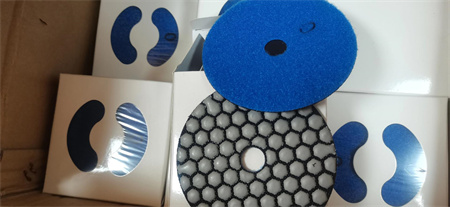

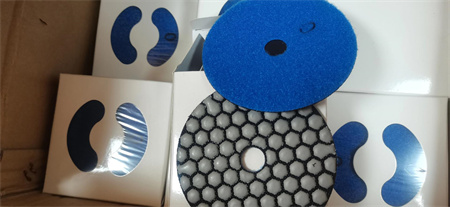

Gone are the days when polishing pad production relied solely on manual labor. With the introduction of automated systems, the precision and consistency in manufacturing have reached new heights. Automated machines ensure that each pad is produced to exact specifications, reducing the risk of human error. This results in a higher quality product that meets the demanding standards of customers worldwide. Whether for polishing granite, marble, or concrete, the pads produced with automation are more uniform and perform consistently across different surfaces.

Automation also offers substantial time and cost savings. Where manual processes once consumed hours of labor, automated systems can complete tasks much faster and more efficiently. This means that production output has increased, allowing manufacturers to meet the growing demand for polishing pads. Furthermore, by reducing the need for manual labor, companies are able to optimize their workforce and direct human resources to more complex, value-added tasks.

At the same time, automation helps to maintain sustainability in production. With tighter control over material usage, waste is minimized, which is a crucial factor in today’s environmentally-conscious market. The ability to precisely manage resources not only boosts efficiency but also contributes to reducing the environmental footprint of the production process.

For global businesses like ours, automation in polishing pad production has unlocked new levels of scalability. As demand increases across international markets, automated systems enable us to scale production without sacrificing quality or efficiency. In this fast-paced and competitive industry, staying ahead requires constant innovation, and automation has proven to be one of the key drivers of that progress.

In conclusion, the impact of automation on polishing pad production is undeniable. It has revolutionized how we manufacture, delivering higher quality products at a faster pace and at a lower cost. As we continue to adopt and improve upon automation technology, the future of polishing pad production looks brighter, with even more advanced systems on the horizon to further enhance the process.