The Potential of AI in Diamond Pad Manufacturing

In the ever-evolving world of manufacturing, technological advancements have played a pivotal role in driving efficiency, precision, and innovation. Among these, artificial intelligence (AI) is quickly emerging as a game-changer, particularly in industries where precision is non-negotiable. One such industry is diamond pad manufacturing. These pads, often used in the semiconductor and electronics sectors, require exceptional accuracy and consistency to meet high-quality standards. As demand for higher-performing materials grows, AI stands poised to revolutionize the way these pads are produced, from design to quality control.

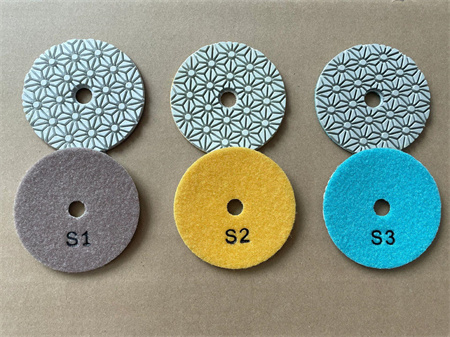

Diamond pads are essential components in chemical mechanical planarization (CMP), a process that smooths and polishes surfaces during semiconductor manufacturing. The pads themselves are intricate, with microscopic diamonds embedded in a matrix material, and they must deliver exceptional durability and precision. The challenges in manufacturing these pads are numerous: ensuring uniform diamond distribution, maintaining consistency in quality, optimizing production speed, and reducing waste. AI presents an opportunity to tackle these hurdles in ways that were once unimaginable.

One of the most significant ways AI is transforming diamond pad manufacturing is through advanced predictive maintenance. Traditional methods of monitoring equipment health rely heavily on manual inspections and scheduled check-ups, which can be time-consuming and sometimes fail to catch subtle issues before they escalate. AI, however, can analyze vast amounts of real-time data from sensors embedded in production machinery, identifying patterns and anomalies that human operators might miss. By predicting when a piece of equipment is likely to fail or require maintenance, manufacturers can prevent unexpected downtime, reduce repair costs, and improve the overall efficiency of the production line.

On a broader scale, AI is also contributing to a more sustainable approach to diamond pad manufacturing. The process of creating these pads can be resource-intensive, involving the use of both natural and synthetic diamonds, as well as other materials that may contribute to waste. AI can optimize the manufacturing process to minimize material usage and reduce waste. For example, AI algorithms can predict the optimal amount of diamond material needed for each pad, ensuring that no excess is used. This not only lowers production costs but also contributes to more sustainable manufacturing practices. Furthermore, AI can help identify ways to recycle or repurpose waste materials, further reducing the environmental footprint of production.

The potential of AI in diamond pad manufacturing is undeniable. As the industry continues to embrace these advanced technologies, the result will likely be smarter, faster, and more sustainable manufacturing processes that meet the ever-growing demands of the high-tech world. For manufacturers, those who harness the power of AI will not only stay ahead of the curve but also drive the future of precision manufacturing.