How China’s Advanced Manufacturing Boosts Diamond Polishing Pad Exports

In the ever-evolving world of diamond polishing technology, China has emerged as a major player, driving the global market with its high-quality diamond polishing pads. With cutting-edge manufacturing capabilities, innovative approaches, and a keen understanding of international demand, Chinese manufacturers are reshaping the landscape of diamond pad production, making their mark worldwide.

The strength of China’s manufacturing lies not only in the scale of production but also in the sophistication of its processes. As global industries increasingly demand products that combine durability, precision, and efficiency, Chinese factories have been able to meet these needs through advanced machinery and automation techniques. This has resulted in polishing pads that not only perform consistently but also last longer, offering exceptional value to users across various sectors, including construction, automotive, and stone industries.

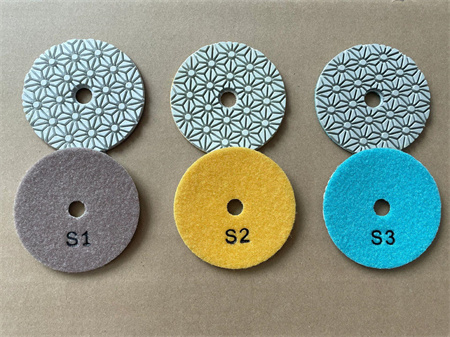

What sets Chinese manufacturers apart is their ability to combine traditional craftsmanship with modern technology. By investing heavily in research and development, they continually enhance product quality, optimizing the design and functionality of diamond polishing pads. This focus on innovation has allowed Chinese products to keep pace with the latest global trends and standards. Whether it’s improving the pad’s surface design for better performance or using more durable materials for increased lifespan, the Chinese market remains at the forefront of these advancements.

Another key factor driving the success of China’s diamond polishing pad exports is its competitive pricing. Leveraging the country’s robust supply chains, manufacturers are able to offer products at a fraction of the cost compared to competitors in other regions. This makes Chinese-made diamond polishing pads an attractive choice for businesses looking to optimize their production costs without compromising on quality.