How Innovations Are Changing the Diamond Polishing Pad Industry

One of the most impactful changes in recent years has been the development of new materials that improve the durability and cutting power of diamond polishing pads. Traditional pads, while effective, often faced limitations in terms of lifespan and consistency. Innovations in synthetic diamonds, for instance, have led to pads that last longer and perform better across a variety of surfaces. These pads now provide superior results with reduced wear and tear, increasing their appeal to industries such as construction, automotive, and stone processing.

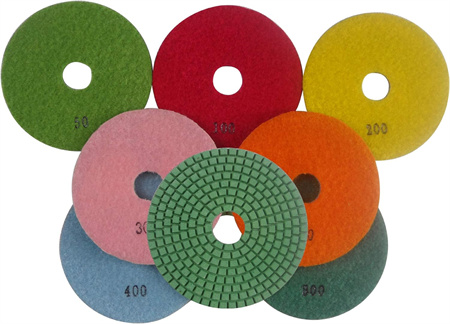

Equally significant are advancements in pad design and construction techniques. Manufacturers have embraced new technologies that allow for more precise control over the pad’s surface texture and consistency. This has resulted in polishing pads that are not only more efficient but also able to handle a broader range of materials, from concrete to marble, granite, and even glass. The ability to fine-tune these pads to suit specific polishing needs has given businesses an edge by allowing them to offer tailored solutions to their customers.

The integration of digital technology into the manufacturing process has also been a game-changer. Today, many factories utilize automated systems and smart technology to monitor and adjust the production process, ensuring that every diamond polishing pad meets the highest standards of quality. Real-time data collection helps optimize production, reduce defects, and improve the overall efficiency of operations. This level of precision ensures that manufacturers can meet the growing demands of an increasingly competitive global market.

Sustainability is another key area where innovation is making a difference. As environmental concerns continue to rise, manufacturers are exploring eco-friendly materials and processes. Some companies have shifted towards using more sustainable synthetic diamonds and environmentally safe resins, minimizing their environmental footprint without compromising the quality of the product. This shift is not only beneficial for the planet but also resonates with customers who are becoming more conscious of the products they use.

In conclusion, the impact of innovation in the diamond polishing pad industry cannot be overstated. From advanced materials and smarter manufacturing processes to sustainability initiatives, these developments are setting new standards and pushing the boundaries of what’s possible. As the industry continues to evolve, the future looks brighter, more efficient, and more sustainable than ever before.