If you’re in the market for high-quality 5 inch polishing pads, sourcing directly from a trusted factory in China can provide the best value. These pads are essential tools in various industries, from automotive detailing to floor care, and China remains one of the top manufacturers offering bulk wholesale options.

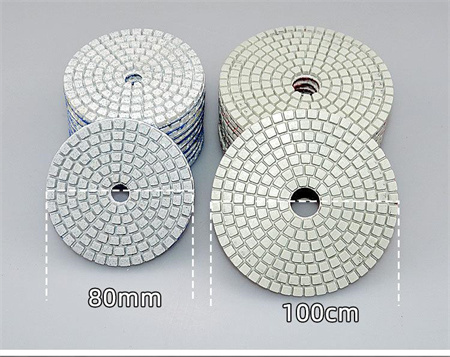

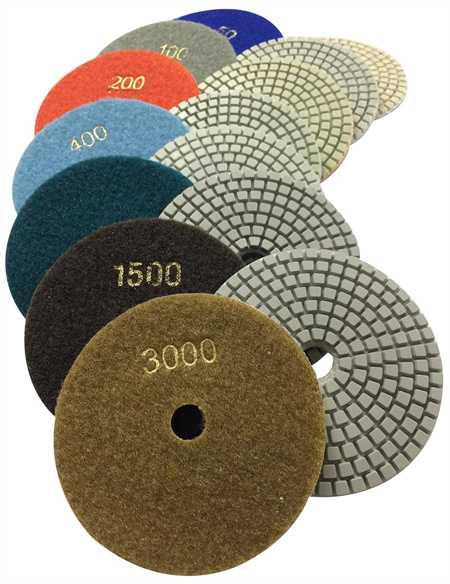

China has built a reputation for producing durable, cost-effective polishing pads that meet global standards. Many manufacturers specialize in crafting pads that cater to different needs, whether you’re polishing delicate surfaces or tackling heavy-duty industrial projects. The 5 inch size is particularly popular, offering the perfect balance of control and coverage, making it a go-to choice for professionals.

What makes China a preferred location for purchasing polishing pads? The answer lies in a combination of factors: advanced manufacturing processes, strict quality control measures, and the ability to customize products to meet specific requirements. Plus, Chinese factories often offer competitive pricing, enabling businesses to buy in bulk without breaking the bank.

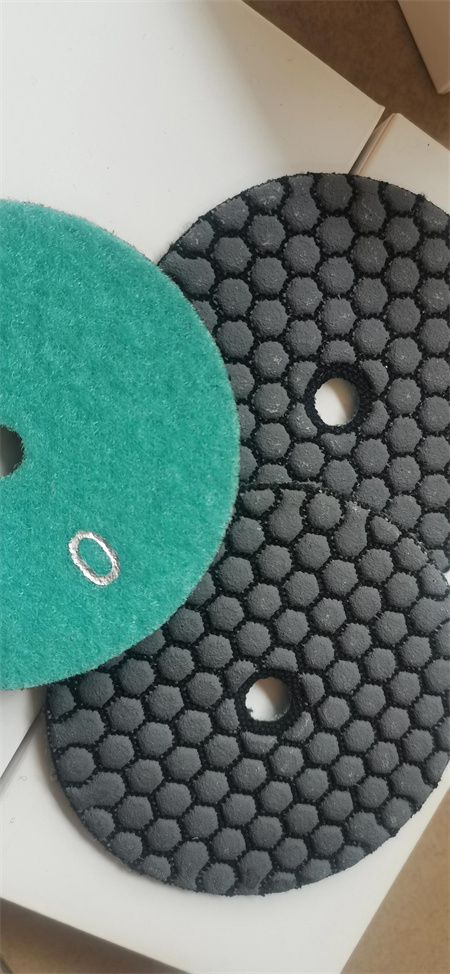

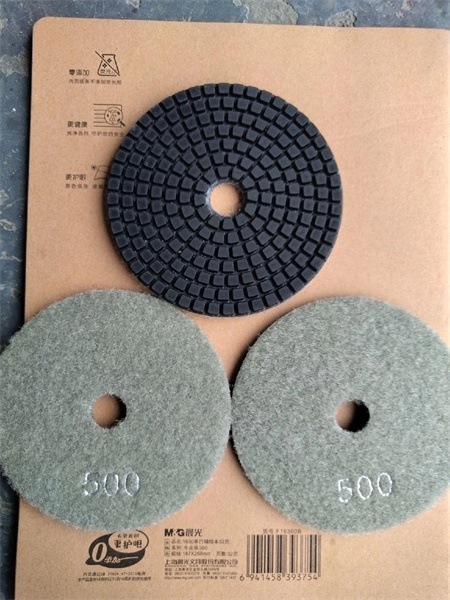

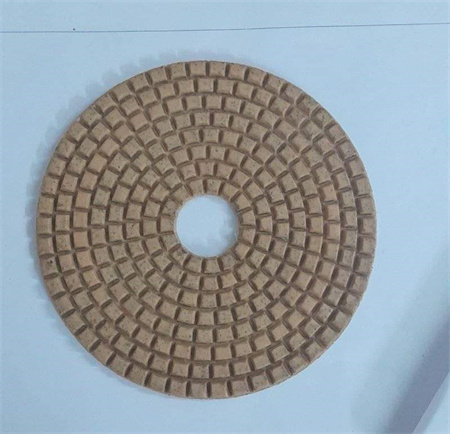

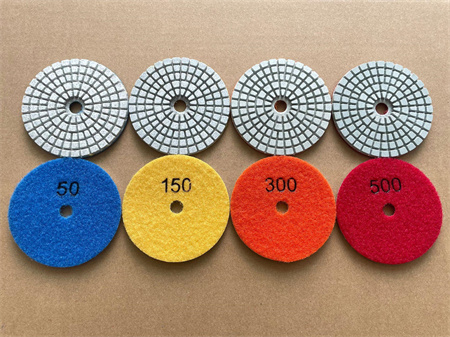

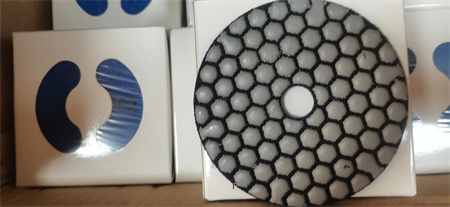

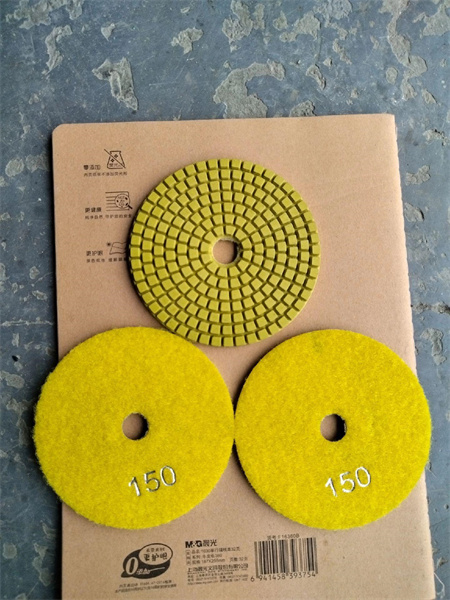

Many of these factories are equipped with state-of-the-art machinery that ensures consistency in every pad produced. From soft pads designed for fine finishing to more aggressive ones for rougher surfaces, the range of polishing pads available is extensive. In addition to standard designs, many factories offer customization options, including different material compositions, colors, and pad thickness, which can cater to specific industries and use cases.

Whether you’re a small business owner or a large-scale distributor, wholesale options from a factory in China mean you’re not only saving on the cost of goods but also benefiting from flexible shipping arrangements and reliable delivery times. Many manufacturers are also open to negotiating terms, ensuring you get the best deal for the quantity you need.

One of the key advantages of buying wholesale from Chinese factories is the opportunity to build a long-term partnership. Many factories offer excellent after-sales support, helping you troubleshoot any issues that may arise during use. They also provide technical assistance to ensure the pads are being used in the most efficient way possible, maximizing their lifespan and performance.

For businesses looking to stay ahead of the competition, investing in quality 5 inch polishing pads from a trusted Chinese manufacturer is a smart choice. Whether you’re in the automotive, construction, or cleaning industry, these pads are versatile tools that deliver exceptional results and meet a variety of polishing needs. So, if you’re ready to elevate your product offering, look no further than wholesale 5 inch polishing pads straight from China’s leading factories.